- Previous blog

- Next blog

- Huyett Marketing Department

- 07/15/2020

Huyett is unique in the breadth of its manufacturing operations and product offerings. We proudly manufacture or source a wide‑range of hard-to‑find products from around the globe to make it easy for you to get what you need. Our manufacturing capabilities are complemented with a state‑of‑the‑art, world‑class warehouse featuring over 100,000 non‑threaded fasteners and industrial components. Whether you need one part, or thousands individually bagged and/or labeled with your brand, we offer customized solutions for manufacturing, packaging, and delivery.

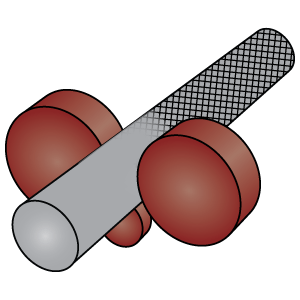

Centerless Grinding

Centerless grinding is an abrasive machining process used to remove material from a workpiece efficiently to produce a high volume of parts in a short time. Material, supported by a blade or work rest, is passed between two rotary grinding wheels without the use of a spindle or fixture to secure the workpiece.

Drilling

Usually performed during turning or milling operations, multi‑tooled turrets can be configured to drill transverse holes, bore internal holes, or ream straight, tapered, or cylindrical holes.

Forming

Forming reshapes a workpiece without adding or removing material by rolling, extruding, die forming, forging, or indenting to create roll splines, gears, worms, and threads. Parts may also be broached using a toothed tool to efficiently remove and shape material on a lathe or an arbor press.

Laser Cutting

Good for short runs where tooling costs can be prohibitive, lasers use a high‑energy beam supported by a coaxial supply of cutting gas to melt, vaporize, and/or combust material in a small and concentrated area. Lasered parts are generally flat – such as washers – but parts can also be bent at angles following laser work.

Marking

Huyett has automated inkjet printing and engraving capabilities that mark (print) your name or part number directly onto your finished parts along with dimensional information using RoHS compliant ink. Finished parts can also be bagged or boxed with your company’s branding in quantities of your choosing.

Milling

Milling is used to shape or modify the tolerances (dimensions) of parts, to install steps or cutouts, to drill and tap holes with exact precision, or to deburr parts. We offer an extensive range of tooling, tool holding, and insertion options capable of producing just about anything.

Sawing

Huyett utilizes metal‑cutting band saws to make precise, uniformly cut key stock and machine keys to tight tolerances. We have the world’s largest selection of 1′, 3′, and 12′ lengths of key stock in plain carbon or zinc plated steel, special grades, and nonferrous material up to 3″ square.

Stamping

Stamping, also referred to as punching, is a process of using a hydraulic press to punch through material and into a die to create a hole in the workpiece. Generally, more than one part can be punched in a single stroke for higher volume applications. A progressive set of dies can also be used to form more complicated designs.

Surface Grinding

In order to guarantee precise tolerances for your parts, Huyett offers surface grinding — a machining process in which abrasive particles, bonded to a grinding wheel, remove small amounts of material from a workpiece. Parts are held in place magnetically to assist in efficient and streamlined production.

Tumbling

After being machined, parts are tumbled to tight tolerances before being cleaned and dried. The cleaning and drying process also introduces rust inhibitors that extend the shelf life of plain finish parts. Additionally, Huyett employees wear gloves to prevent exposing finished parts to oils and impurities.

Turning

Our experienced lathe operators can turn, face, part, or groove complex parts with tight tolerances including the formation of a head (clevis pins) or radial grooves (headless pins).

Wire Forming

Many parts such as cotter pins, hitch pin clips, rings, and hooks are manufactured using a process called wire forming. Round, square, and shaped wire may be pulled through dies, extruded, bent, or coiled to suit your needs. We offer hundreds of standard wire forms or can customize to your specifications.

Our Engineering Handbook is a great companion resource. From hot rolls to cold saws, it provides a fresh perspective on steelmaking from iron ore to finished product. You’ll learn about different grades of steel and finishes, testing steel hardness, heat treating steel, and mechanical properties of steel. Metric and imperial conversion charts are included along with case studies detailing some of the challenges we have solved with cost‑effective solutions.

Learn More About Manufacturing At Huyett