- Previous blog

- Next blog

- Huyett Marketing Department

- 03/02/2023

- Updated 10/26/2023

Parts are rarely labeled with one universal name in the fastener world. While names may differ, in many cases they are understood to describe the same part. But this isn’t the case for all fasteners – which is why a common debate remains: what is the difference between a

bushing and a bearing?

bushing and a bearing?

This is a confusing question because many auto shops, hardware stores, and fastener manufacturers and distributors may call out their own differences between the fasteners. However, as naming systems across the industry are unique to different entities, the confusion arises when, for example, a specific function aligns with a bushing on one website and a bearing on another.

While there will never be a definitive answer to this question, there are a few ways to clear the muddy water. By focusing on functionality and a few specific terms, you can ensure you acquire the right part for your application.

Bearings and Bushings: Definitions

There are two definitions to keep in mind as we explore this topic. These definitions are generally accepted across the industry, which helps establish boundaries for the fasteners’ functionality.

Bushing:

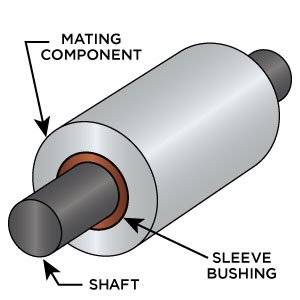

A hollow, single-component cylinder that reduces friction between a shaft and a bore, alters the size of the bore, and guides or constricts the motion of its mating shaft (the broader definition of the two).

A hollow, single-component cylinder that reduces friction between a shaft and a bore, alters the size of the bore, and guides or constricts the motion of its mating shaft (the broader definition of the two).

Bearing:

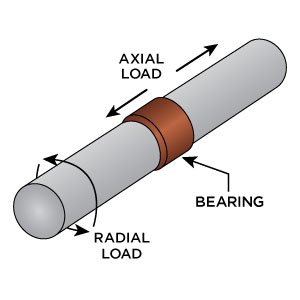

A fastener that bears the load

of an application and reduces friction between a shaft and a bore. Specific types allow for high-speed radial motion; commonly referred to as journal bearings.

A fastener that bears the load

of an application and reduces friction between a shaft and a bore. Specific types allow for high-speed radial motion; commonly referred to as journal bearings.

The definitions may be clear, but as we’ll see, many fasteners fit both descriptions.

Bearings and Bushings: The “Difference”

Many explanations will simply state that there is no difference because a bushing is a type of bearing. While this isn’t

untrue

, it is a surface-level answer because it invites the notion of, “if A is B and B is C, then A is C.” In other words, if bushings were a type of bearing, then subtypes of bushings would also have to be a derivative of a bearing, which isn’t true. Bearings are not the “parent” part.

untrue

, it is a surface-level answer because it invites the notion of, “if A is B and B is C, then A is C.” In other words, if bushings were a type of bearing, then subtypes of bushings would also have to be a derivative of a bearing, which isn’t true. Bearings are not the “parent” part.

Bushing

is more of a generic term that catches most of the single-component members of this fastener family. Many bushings bear loads or allow for rotational movement, and many bearings reduce friction; all of these parts will alter the size of a bore. So why even distinguish between the two?

is more of a generic term that catches most of the single-component members of this fastener family. Many bushings bear loads or allow for rotational movement, and many bearings reduce friction; all of these parts will alter the size of a bore. So why even distinguish between the two?

There are a few specific fasteners that are definitively a

bushing

or a

bearing

based on the definitions above. Beyond these few, the difference between a bushing and a bearing at a practical level is how it is used, not how it is designed.

Since fastener manufacturers, distributors, and hardware stores cannot predict how you will use a part, their names for the fasteners are somewhat arbitrary (outside of the few exceptions described later).

bushing

or a

bearing

based on the definitions above. Beyond these few, the difference between a bushing and a bearing at a practical level is how it is used, not how it is designed.

Since fastener manufacturers, distributors, and hardware stores cannot predict how you will use a part, their names for the fasteners are somewhat arbitrary (outside of the few exceptions described later).

Take a look at these two fasteners:

Sleeve Bearing

Flange Bearing

Huyett calls these fasteners

sleeve

and

flange bearings

. They are single-component cylinders, but they are typically used to bear radial loads. You will probably see them in other places listed as plain journal, slide, or solid bearings; plain or sleeve bushings, etc.

sleeve

and

flange bearings

. They are single-component cylinders, but they are typically used to bear radial loads. You will probably see them in other places listed as plain journal, slide, or solid bearings; plain or sleeve bushings, etc.

Outside of deep engineering debates, all of these names are correct. It is more important to know what your fastener should do than what it is called.

Determining Functionality

Rather than getting caught up in the names of your fasteners, you need to understand how you’ll need them to work. It is helpful to narrow in on the following elements and requirements of your application before searching for your part:

- Shaft and bore size

- If the fastener is new or will replace an old part

- Load bearing requirements

- Desired shaft motion

- Shaft rotation speed if rotation is needed

- Lubrication requirements

- Shaft and bore material strength and hardness

Knowing the requirements of your application will help you pick the right part based on capability. You may begin your search thinking you need a sleeve bearing, but you may miss out on selecting the right fastener if you don’t open your search up to bushings. It is important to

work with sales experts who understand part functionality; they will help guide your inquiry with questions about the desired part capability, regardless of what it is called.

work with sales experts who understand part functionality; they will help guide your inquiry with questions about the desired part capability, regardless of what it is called.

For design application considerations, you should consult with qualified engineers (not Sales Support) to ensure application criteria are met.

The Material

In most cases, whether the fastener is acting as a bushing or a bearing, the material should be softer than the mating components. It needs to keep the shaft and bore from wearing, maintain durability, and most importantly, take the brunt of the friction. Usually, this means the material should be

sacrificial

(wear before the shaft and bore). It should also be able to:

sacrificial

(wear before the shaft and bore). It should also be able to:

- Withstand rotational or linear speed requirements

- Withstand application temperature

- Absorb particles to protect the shaft or bore

- Resist corrosion

- Support the application load

Bronze

While several materials support these requirements (depending on the shaft and bore material), one of the most common is bronze. Bronze is particularly suited to reduce friction between two metals and is usually more malleable than most shaft or bore metals. Many parts are machine-cut from

bronze stock or bars, but

sintered

bronze often offers the added bonus of self-lubrication:

bronze stock or bars, but

sintered

bronze often offers the added bonus of self-lubrication:

Metal Sintering:

A process in which powdered metal is pressed or poured into part dies or casts and heated until just under its melting point, cooled, and removed from its casing as a hardened part. Sintered parts tend to be porous, so in many cases they are impregnated with oil to provide self-lubrication. Sintered bronze bearings do not require regular grease or oil maintenance.

A process in which powdered metal is pressed or poured into part dies or casts and heated until just under its melting point, cooled, and removed from its casing as a hardened part. Sintered parts tend to be porous, so in many cases they are impregnated with oil to provide self-lubrication. Sintered bronze bearings do not require regular grease or oil maintenance.

Cast

bronze also works well because of its strong granular structure developed through the hardening process, which lends itself to parts that need more load endurance (like machinery bushings).

bronze also works well because of its strong granular structure developed through the hardening process, which lends itself to parts that need more load endurance (like machinery bushings).

Specific Types of Bearings and Bushings

As we’ve mentioned, a few specific categories of bushings and bearings are only called by their respective names because they are not cross-functional.

Dowel Bushings

The sole purpose of a dowel bushing is to take up play between a dowel pin or bolt and a hole with precision alignment. While they are also called spring alignment dowels or ground hollow dowels, they are not referred to as “dowel bearings” because they are not load-bearing.

Dowel bushings are carbon steel bushings that feature a thin, staggered split shaft with beveled chamfers on both ends. The split shaft gives it spring action to help with precision alignment while also stopping the contraction at a fixed point, and the chamfers help provide a smooth installation.

Tension Bushings

Tension bushings are also widely understood to be bushings (sometimes called split bushings, split steel bushings, or spring bushings). This is likely because they function almost the same as a dowel bushing.

Tension bushings are steel bushings that look like dowel bushings, except the shaft is split with a straight line rather than a staggered one (which allows for flexible contraction). They act as a friction barrier between the shaft (which most likely won’t be a dowel pin) and the bore, but do not provide the same precision tolerance as a dowel bushing. Tension bushings work well in high-impact scenarios, which may differ from precision applications where a dowel bushing would be more appropriate.

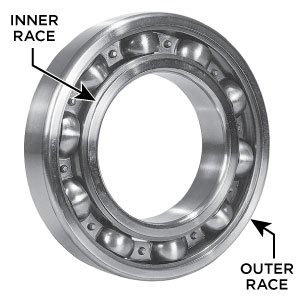

Ball Bearings

Ball bearings, also called conrad bearings, specifically bear the load of a rotating shaft or bore and allow for rotational speed. While they may take up play as a result of their main function, they do not constrict motion. Their design is one of the few types that require harder material than the mating shaft and bore.

These fasteners are a type of bearing that encases

precision metal balls in between two metal circles (called races). The balls separate the races from each other and allow for a rolling movement, which means either the inner or the outer race will stay stationary as the other one rotates. Most ball bearings are ideal for low load-bearing scenarios because of the space in between the balls and the single contact point with the races. However, this design can compensate for misalignment between the two races.

precision metal balls in between two metal circles (called races). The balls separate the races from each other and allow for a rolling movement, which means either the inner or the outer race will stay stationary as the other one rotates. Most ball bearings are ideal for low load-bearing scenarios because of the space in between the balls and the single contact point with the races. However, this design can compensate for misalignment between the two races.

A few simple examples of ball bearing applications are skateboard wheels or toys like fidget spinners and yoyos, where frictionless spinning is the main behavior of the product.

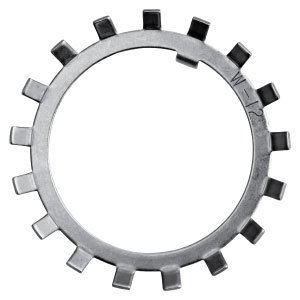

Bearing Lock Nuts and Washers

Bearing lock nuts, also known as shaft lock nuts or bearing retaining nuts, are thick rings with slots on the outside that interlock with bearing lock washers, which feature multiple metal tabs on the outside diameter and one internal tab to keep it from rotating. The washer is placed onto a keyed shaft, and the nut threads onto the shaft until it flattens the washer. The tabs of the washer are then bent up into the notches of the nut to secure it in place.

For more information on the interaction of these two fasteners, visit our

How to Use Lock Nuts and Lock Washers guide.

How to Use Lock Nuts and Lock Washers guide.

Bearing Lock Nut

Bearing Lock Washer

Roller Bearings

Roller bearings behave in much the same way as ball bearings, but the rolling elements are cylindrical and placed closer together. This makes them the better choice for higher loads because the rollers make complete contact with the races. However, they don’t allow for as much speed. Roller bearing applications include wind turbines, agricultural equipment, and applications with slow, heavy loads.

Machinery Bushings and Thrust Bearings: The Difference

Machinery bushings and thrust bearings can cause confusion on their own because they both look like washers. However, a quick list of definitions will help delineate between the three parts:

Washers:

Used to distribute the load of other compressing fasteners.

Used to distribute the load of other compressing fasteners.

Machine Bushings:

Washer-shaped carbon steel fasteners with a much wider range of thicknesses and inner diameters; used as

shims and spacers.

Washer-shaped carbon steel fasteners with a much wider range of thicknesses and inner diameters; used as

shims and spacers.

Thrust Bearings:

Washer-shaped cast bronze fasteners that bear thrust loads and help align components on a shaft.

Washer-shaped cast bronze fasteners that bear thrust loads and help align components on a shaft.

While these fasteners look similar, the important differences are in their thicknesses, diameters, and materials. Varying thicknesses and diameters allow the bushings and bearings to fit over different-sized shafts and create custom spacing alignment. The material determines how well the fastener will absorb a thrust load.

Finding the Right Bushing or Bearing

It is important to work with people who know how to ask the right questions about bushings and bearings. Huyett’s Sales Team understands that part names may not match expectations, so they help you start your search with questions regarding functional requirements first.

Call or email Huyett to find the fasteners you’re looking for.

Call or email Huyett to find the fasteners you’re looking for.

For more information about Huyett’s Bushing and Bearing product lines,

visit our FAQ page.

visit our FAQ page.