key words:small progressive cavity pump,small progressive cavity pump

The screw pump working part is composed of rotating eccentric rotor and stator. The rotor and stator have two contact points in every transverse section. These contact points from two sealing lines along the working parts of rotor (or stator).

Thus comes into one or a few sealing chambers when the rotor rotating. The media entering the sealing chamber remove smoothly from suction end to discharge end along the sealing chamber. During the whole running, the pressure pulsation is very low which has no any effect upon the intrinsic construction of pumped media.

We can produce all kinds of substitutes, the quality is the same as the original, can also meet the needs of various materials. The same wall thickness stator and hollow rotor is our characteristic process, its heat dissipation and pressure resistance is better than the same grade of stator and rotor. Therefore, we have more solutions for the diversified needs of customers.

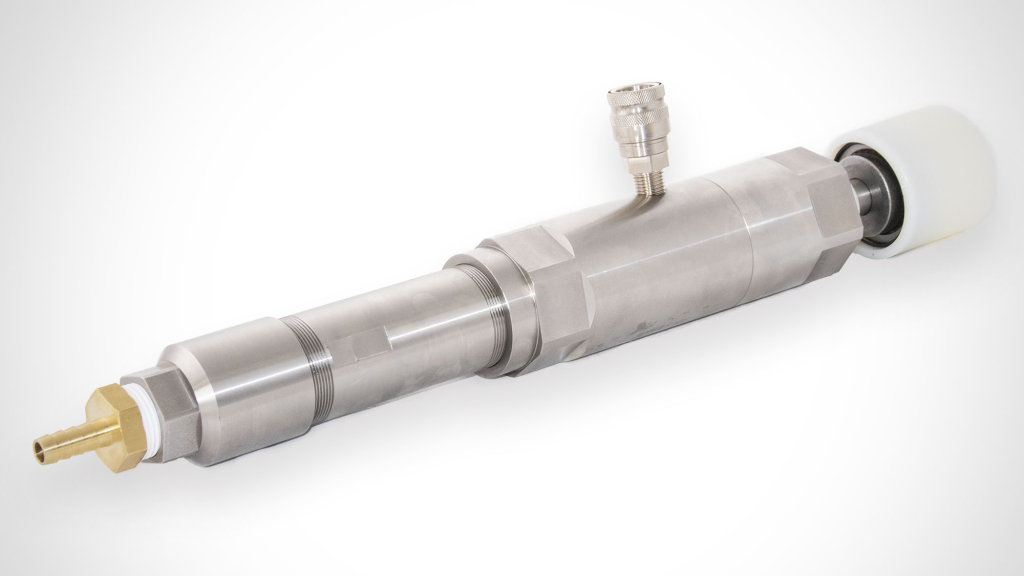

It consists of two parts: driving unit and conveying unit. It is equipped with a needle nozzle and a pump whose liquid output is controlled by a control system.

The micro progressive cavity pump realizes the medium conveying function through the directional rotation of the rotor in the stator cavity.

The transportation process does not have any influence on the medium performance.

At the same time, the reverse rotation of the motor can easily realize the function of medium suction, ensuring the cleanness of medium and materials, no dripping and no pollution!

It is a revolutionary product of viscous flow precision micro-transportation, with a minimum flow rate of 0.001ml and an accuracy of 1%. It has the unique advantages of constant flow rate, being able to suck back, being suitable for granular media, and the flow rate is not affected by changes in viscosity and pressure. It is widely used for precise quantitative transportation, gluing and potting of various fluids.