- Previous blog

- Next blog

- Huyett Marketing Department

- 06/01/2023

High pressure grease fittings – also known as pressure control grease fittings, pressure relief grease fittings, or high pressure zerk fittings – prevent damage to lubrication applications by ensuring that pressure never exceeds a predetermined maximum.

Lubrication applications function best when their internal pressure is within a range determined by their design and construction. During operation, gasses and lubricants expand as temperatures rise, which may cause pressure to increase beyond the desired range.

Regreasing may also cause pressure to rise in a lubrication application, since grease guns deliver grease at a high pressure.

If the pressure exceeds the predetermined threshold, parts may wear more quickly, high pressure churning may reduce efficiency, seals may break, and the life of the component may be reduced. High pressure grease fittings extend the life of machine components.

What are High Pressure Grease Fittings?

High pressure grease fittings (or zerk fittings) refer to pressure-relieving components that maintain internal pressures in a lubrication application. If pressure increases beyond the threshold, the fitting manages gasses and lubricants until the desired operating pressure is re-established.

Here’s the catch – not all of them are actually zerk fittings. The term

high pressure grease fittings

is an umbrella term that encompasses fittings that accept grease and maintain its flow and fittings that only regulate pressure in a zerk fitting application.

high pressure grease fittings

is an umbrella term that encompasses fittings that accept grease and maintain its flow and fittings that only regulate pressure in a zerk fitting application.

These two types of fittings are split into two specific categories: flow control grease fittings and pressure control grease fittings.

Flow Control Grease Fittings

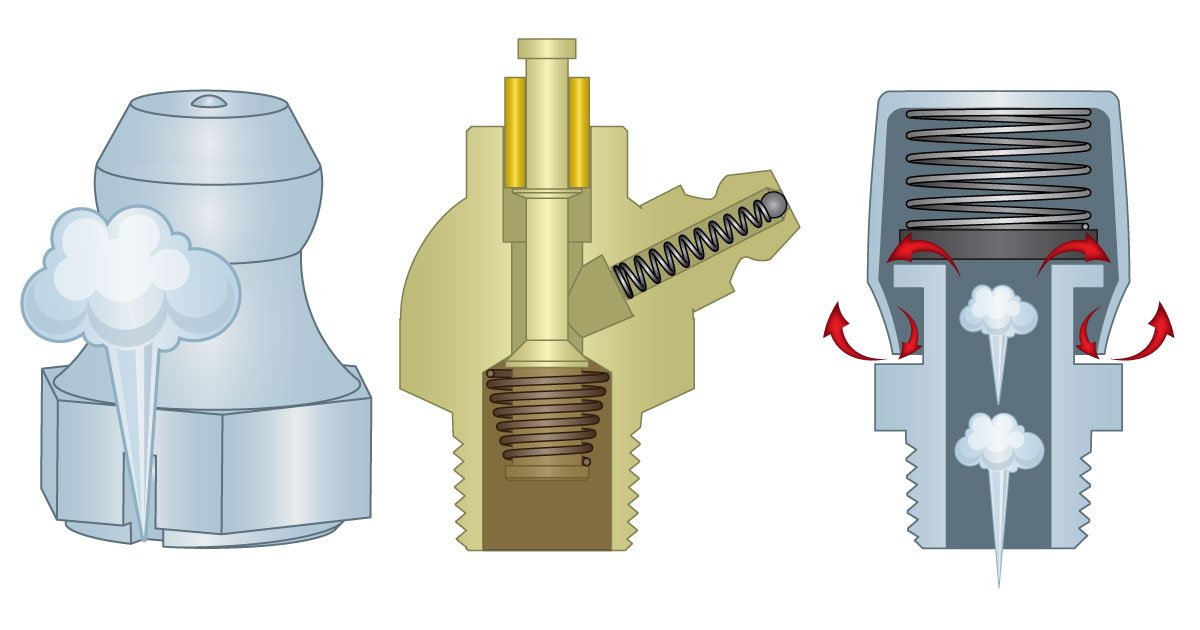

Flow control fittings – also called hydraulic shut off fittings – are technically grease fittings; they accept grease and offer added pressure relief mechanisms by controlling its flow through safety vents and leak proof or flow stop technology.

Before using these fittings, make sure to verify the proper pressure rating for your application and ensure they coincide with the pressure capacity of the fitting. Leak proof and flow stop fittings will provide specific maximum pressures; safety vents will simply expel grease when it overflows.

Safety Vents

Safety vents have a milled slot in the shank to relieve pressure during operation. It is inexpensive and simple in design; the part excretes excess grease through the slot into the work area when the application is over-pressurized. A safety vent’s main disadvantage is that it contaminates the work area with the grease overflow.

Leak Proof

Leak proof fittings actually allow for extra pressure by accommodating added grease. They feature a steel or rubber ball check that deforms to create extra space for more lubrication. It also features a seal so that grease cannot leak out when under pressure.

The leak proof design is desirable in environments where grease should not contaminate the work surface; they are often found in food processing or pharmaceutical applications.

Light Oil Leak Proof

Like the leak proof fittings, these fittings accommodate additional lubrication but are meant for lower PSI environments with light oil. Except for a plastic ball check that can deform on the inside of the tip when under pressure, they are designed the same as regular zerk fittings. The deformation provides a leak proof seal for up to 215 psi.

Flow Stop™

While leak proof fittings control the grease that flows out of a fitting, flow stop fittings control the

input

. Using a valve with a pressure rated spring, the fitting opens and closes to allow grease to flow in at a controlled pressure, which prevents a grease gun from over-greasing the fitting.

input

. Using a valve with a pressure rated spring, the fitting opens and closes to allow grease to flow in at a controlled pressure, which prevents a grease gun from over-greasing the fitting.

How to Install Flow Control Grease Fittings

Since flow control fittings are zerk fittings, they are installed and greased in the same manner as other zerks. Read our

How to Install and Maintain Grease Fittings guide to learn more.

How to Install and Maintain Grease Fittings guide to learn more.

Pressure Control Grease Fittings

Pressure control grease fittings are not actually zerk fittings – they do not accept grease from a grease gun. Their sole purpose is to regulate air and gas pressure in a lubrication application, which they do using three distinct design types: vents, breathers, and relief vents.

Vents

Vents open and close within a predetermined pressure range: As internal pressures rise, a flat seal in the vent (typically composed of rubber) opens, allowing pressure to vent. As the pressure decreases, the seal closes. The rubber seal has the added advantage of sealing the port opening while closed, thus preventing dirt, water, and other contaminants from entering.

The vent opens and closes at a predetermined pressure. The vent seals so that air is only allowed to move out of the assembly.

Breathers

Breather pressure relief fittings feature specially designed ports that allow air to move in and out, creating the effect of “breathing.” They have a special cap which reduces contamination. For additional contamination protection, some breathers are equipped with a felt filter.

Breathers do not restrict airflow, keeping the internal pressure at a safe operating level.

Relief Vents

Pressure relief vents open and close within a predetermined pressure range. As internal pressure rises, the plunger or check ball opens, allowing pressure to vent. As pressures decrease to below the minimum threshold, the valve closes. Relief valves are available in both a top vent and side vent design.

Closed: The basic design consists of a pre engineered spring that controls a pop up valve. At peak performance, the valve is closed, sealing the bearing.

Open: Once internal pressures reach the predetermined opening psi, the pop up valve engages and the fitting allows pressure to escape.

How to Install Pressure Control Grease Fittings

Pressure control fittings are typically installed above the stationary fluid line so that they reduce pressure by venting gasses. If they are fitted below the fluid line, they may vent grease instead.

Pressure control grease fittings are available in a wide range of pressure ratings to suit many environments. Be sure to have the proper pressure control fitting with the correct pressure rating for the application. If a fitting with the wrong pressure rating is installed, venting may not occur before efficiency is affected and components are damaged.

Can You Adjust a Pressure Relief Valve?

Yes. We stock a range of pressure relief valves that can be adjusted within a PSI range. We also stock valves rated for a predetermined pressure.

The Bottom Line

Huyett offers a variety of high pressure grease fittings from flow control to pressure control to help you keep your lubrication application within safe operating pressure ranges. To learn more about our lubrication fittings and accessories, visit our

Product FAQ page or

contact our Sales team today.

Product FAQ page or

contact our Sales team today.