I love laminate. It’s a low cost and extremely durable choice for work surfaces in woodworking shops. Once you learn a few basic techniques with regard to how to size, glue and trim laminate, most woodworkers will find many practical uses for it.

Plastic laminate is the ideal surface for table saw extensions as well as shop made router table tops. The low friction surface works great for in out feed tables because work pieces slide easily with minimal resistance.

The low price per square foot of WilsonArt laminate makes it an affordable option that is impossible to beat. And when you pair all of the features above with the fact it’s easy to work using basic tools, woodworkers of any skill level will enjoy working with and using laminate in the workshop. In one short video I show how to cut laminate using a wide variety of tools.

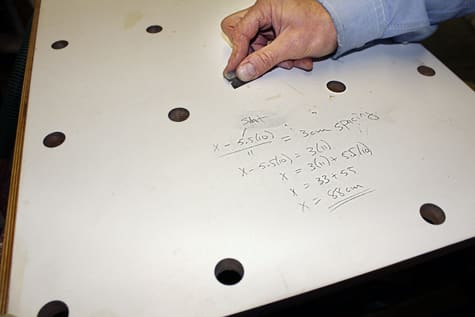

While I love the bright colors of Wilsonart laminate, I prefer white or lighter colors for my shop because you can sketch and make quick calculations in pencil that are easily erased. You can wipe away pencil marks and even use a razor blade to scrape off glue, finish, paint etc…

The Ultimate Multi-Function Work Table

I am a big fan of the Festool system of woodworking tools. When I bought the Festool MFT (multi-function table) and TS55 EQ saw to quickly and accurately cut panels, I really did not grasp the power of the perforated top until I bought the horizontal clamping fixtures (488030) to hold panels in place while cutting. The Festool multi-function table is the ideal tool to dedicate to panel sawing, but I find it much too fragile and small to act as my day in, day out work table. I need a table in my shop that is stout and strong.

I took a 60″ x 60″ sheet of 3/4″ (18mm) Baltic birch plywood, drilled a perforated 20mm hole pattern, and set it on super stout saw horses with lateral steel connectors and voila, my quest for the perfect shop table was realized. I made my own version of the Festool MFT

And after I adhered a piece of Wilsonart laminate to it I knew I had the ultimate low cost versatile woodworking work table.

My table takes a beating 8 days a week and is not anywhere close to needing replacement. And another great feature of laminated top, when you’re ready for a fresh surface, all you have to do is lay the new laminate directly over the old and retrim.

In the videos below I laminate the top of the Mobile Vacuum Work Station that houses my Festool vacuum. In this short series I cut laminate using many different tools. I also show how to apply the contact cement, roll out, file the edges and trim the laminate to the pre-dilled holes in order to make your own laminate Festool mft work table. My first Festool MFT 3 revolutionized my shop, and now I have fabricated all the table tops in my shop to be multi-function styled. Thank you Festool!