Understanding Moyno Parts List: Essential Components for Efficient Pump Operation

When it comes to industrial pumping solutions, Moyno pumps stand out for their reliability and efficiency. The Moyno parts list plays a crucial role in ensuring that these pumps operate at their best, providing seamless service in various applications including wastewater treatment, food processing, and oil extraction. Understanding the components in the Moyno parts list helps operators maintain their systems effectively and enhance their operational longevity.

What is a Moyno Pump?

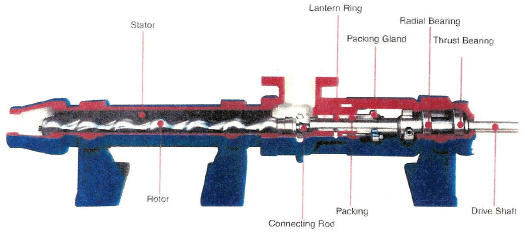

Moyno pumps, known for their progressive cavity design, function by transferring fluid through a series of interconnected chambers. This design minimizes shear stress on the fluid, making these pumps ideal for handling thick or viscous materials. As a result, they are commonly utilized in sectors where consistency is critical, such as chemical manufacturing and food processing.

Importance of the Parts List

A comprehensive Moyno parts list is invaluable for several reasons:

- Maintenance and Repairs: Understanding the components in a Moyno parts list allows for timely maintenance and replacement of worn parts. Regular upkeep not only ensures efficient operation but also extends the lifespan of the equipment.

- Cost Efficiency: Knowing which parts are subject to wear enables businesses to stock spare parts strategically. This preparedness reduces downtime, allowing operations to run smoothly and cost-effectively.

- Compatibility: The Moyno parts list ensures that operators select the correct components that are compatible with their specific pump models. This prevents the installation of parts that might not function well together, avoiding potential operational failures.

Key Components in the Moyno Parts List

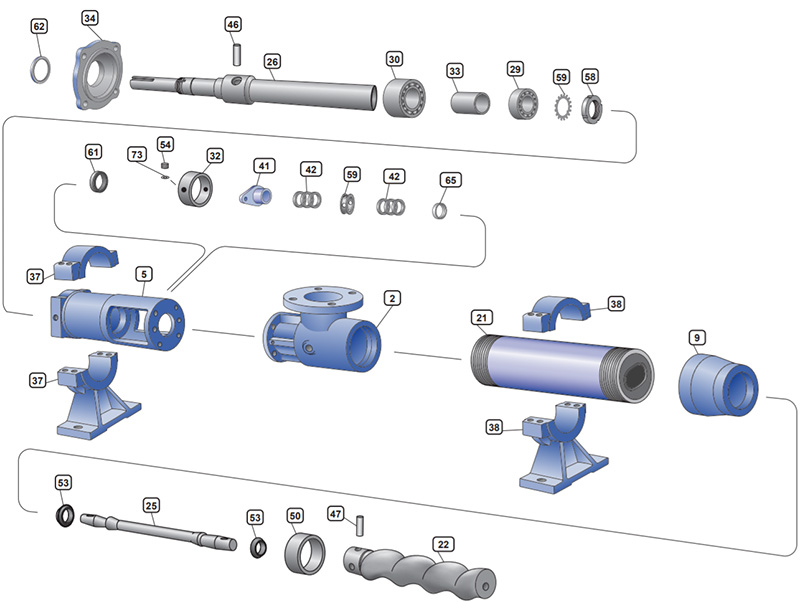

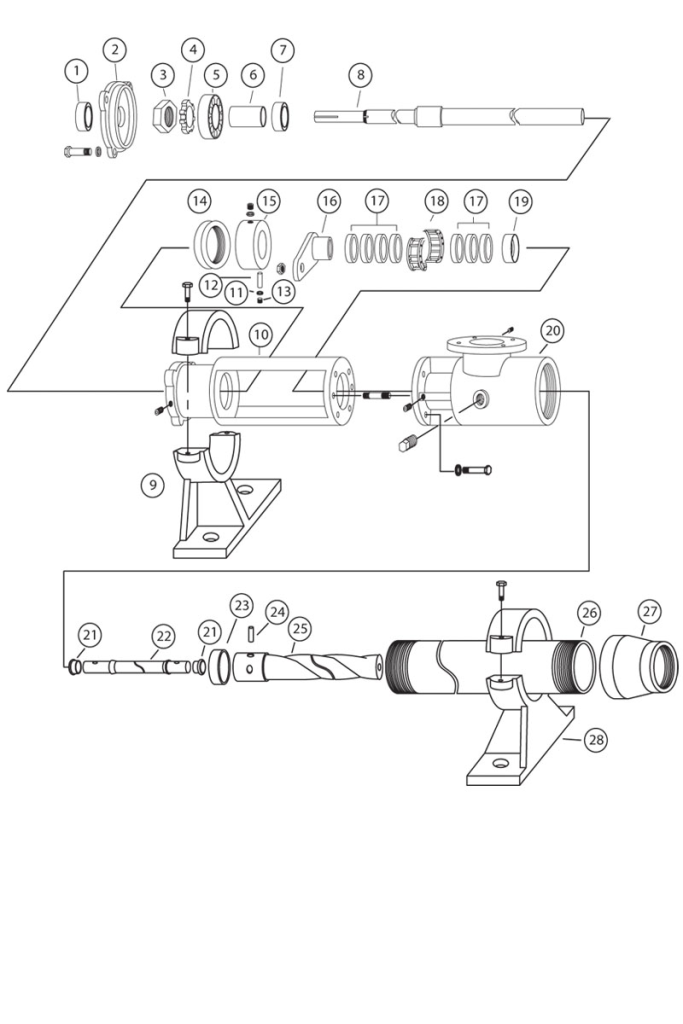

Here are some of the essential components often found in a Moyno parts list:

1. Rotors and Stators

The heart of the progressive cavity pump, rotors and stators work together to create the cavities that transport fluid. It is crucial to replace these parts as they wear out, to maintain efficient flow rates and minimize leakages.

2. Suction and Discharge Hoses

Quality hoses are essential for connecting the pump to the piping system. Over time, hoses can wear down or become damaged due to environmental stressors. Regular inspection and replacement keep the entire system functional.

3. Bearings

Bearings help support the rotating elements in the pump. They come in various materials and sizes, and selecting the right type is critical to the pump’s stability and operational efficiency.

4. Seals and Gaskets

These components prevent leaks at joints and connections. Regular checks and timely replacements of seals and gaskets are vital to ensure that the pumping system remains fluid-tight.

5. Gearboxes and Couplings

Gearboxes transmit power from the motor to the pump, and couplings connect two shafts together. These are critical components that require periodic maintenance to prevent breakdowns in operations.

Benefits of Using a Moyno Parts List

Utilizing a well-structured Moyno parts list offers several benefits:

- Streamlined Repairs: Having detailed information about each component simplifies the process of ordering and replacing parts.

- Enhanced Performance: Regularly updated parts ensure that the pumps operate at peak efficiency, leading to improved performance.

- Reduced Downtime: With a ready supply of essential components, businesses can minimize downtime and maintain productivity.

Conclusion

Understanding the Moyno parts list is essential for operators involved in maintaining and managing Moyno pumps. This knowledge not only aids in effective maintenance but also enhances operational efficiency, reduces costs, and prolongs the life of the equipment. By ensuring that each component is in good condition, businesses can reap the full benefits of their investment in Moyno pumping solutions. Keeping an up-to-date parts list on hand is an investment in reliability, efficiency, and sustained productivity.