Progressing cavity pumps (PCPs) are increasingly popular in various industries, particularly in oil and gas, wastewater treatment, and food processing. Known for their reliability and efficiency in handling viscous fluids, these pumps operate on a unique mechanism that offers a steady flow regardless of the discharge pressure. One of the critical tools for understanding the performance of a progressing cavity pump is the progressing cavity pump curve.

What is a Progressing Cavity Pump?

A progressing cavity pump consists of a helical rotor that turns within a stator, creating cavities that progress along the pump’s length. This design allows the pump to move fluids with varying viscosities and solids content, making it suitable for a wide range of applications. The pump’s unique mechanism provides a constant and pulsation-free flow, which is essential in many industrial processes.

Importance of Pump Curves

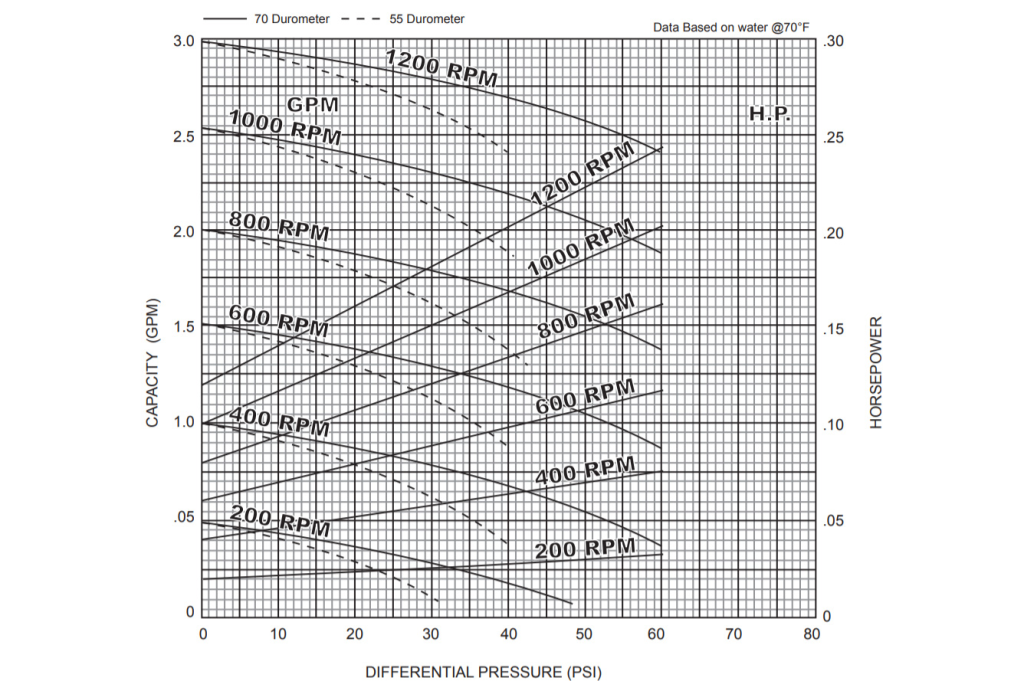

Pump curves are graphical representations that depict a pump’s performance across various operating conditions. For progressing cavity pumps, these curves illustrate the relationship between flow rate, pressure, and efficiency. They are essential for engineers and operators to select the right pump for a specific application, ensuring optimal performance and longevity.

Elements of the Pump Curve

The progressing cavity pump curve typically includes several key elements:

- Flow Rate (Q): Measured in gallons per minute (GPM) or liters per second (L/s), flow rate indicates the volume of fluid the pump can move at a given time.

- Head (H): This represents the pressure the pump can generate, measured in feet or meters. The head curve provides insight into the energy needed to transport fluid vertically.

- Efficiency: This component of the curve indicates how effectively the pump converts input energy into hydraulic energy. Higher efficiency is desirable for cost-effectiveness and reduced wear on the pump.

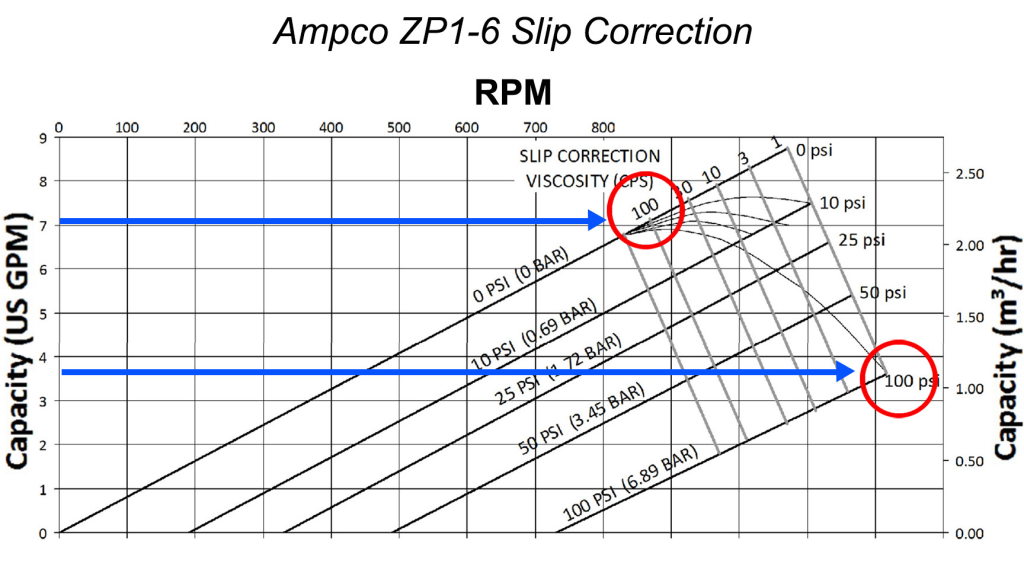

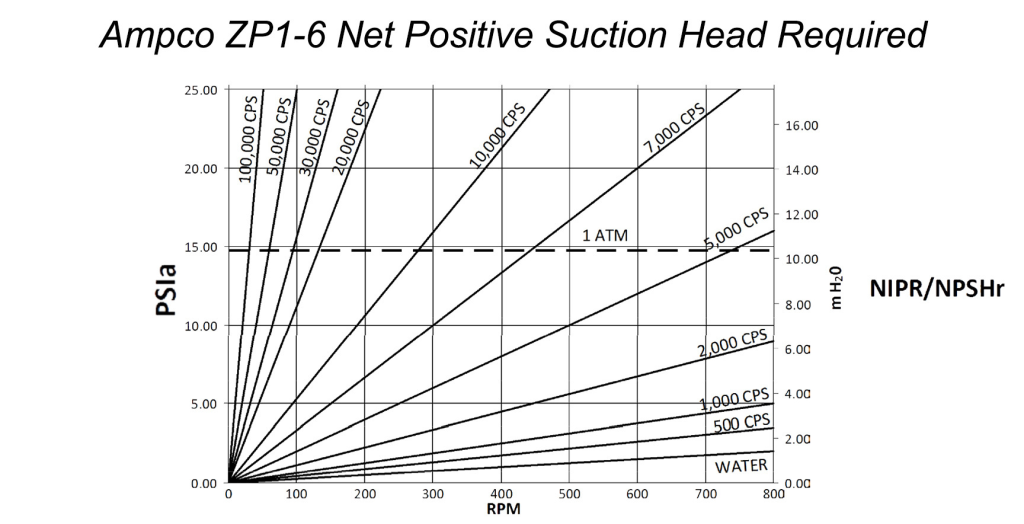

- NPSH (Net Positive Suction Head): NPSH is vital to prevent cavitation, a phenomenon that can damage the pump. The curve helps determine the minimum NPSH needed for safe operation.

Analyzing the Curve

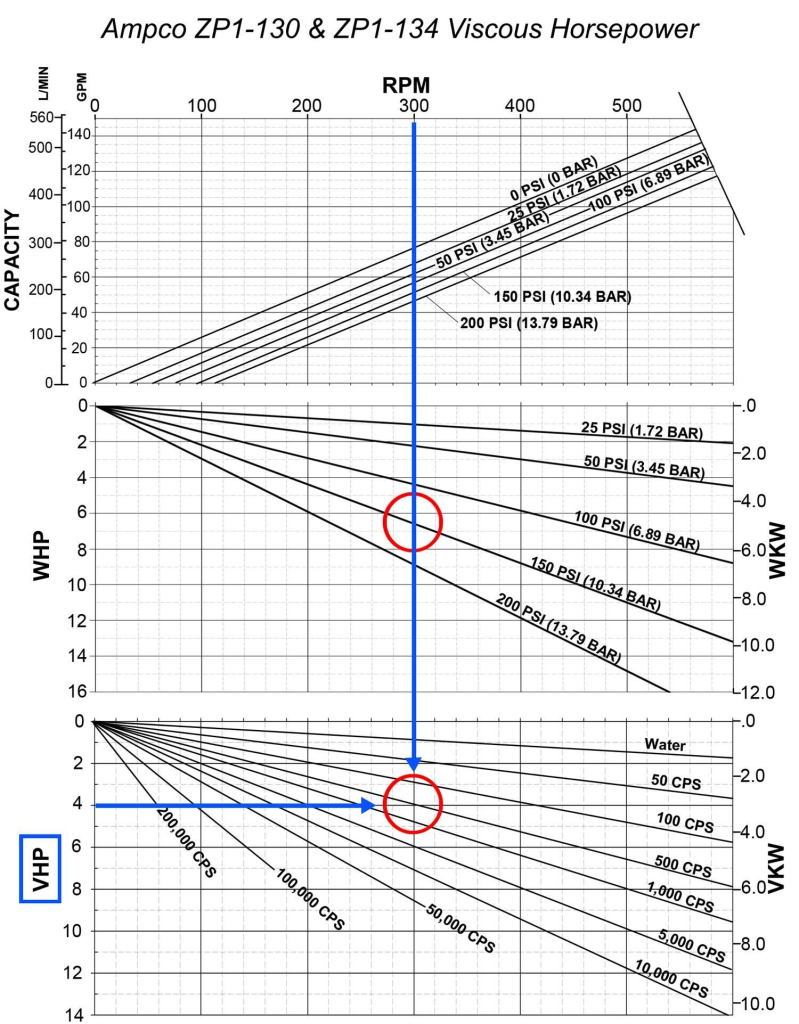

When analyzing a progressing cavity pump curve, operators can identify the optimal operating point where flow rate and pressure meet the required system conditions. This point is crucial because operating outside of this range can lead to issues such as excessive wear, energy inefficiency, and potential pump failure.

For instance, if a pump is consistently operated at a flow rate higher than what the curve suggests as optimal, it may lead to increased friction and heat, reducing the lifespan of the pump components. Conversely, operating at a low flow rate may result in inefficient performance and increased energy costs.

Selecting the Right Pump

Selecting the appropriate pump involves more than just reviewing the progressing cavity pump curve. Engineers must consider the specific requirements of the application, such as the fluid type, temperature, and any solids content.

For example, in the oil and gas industry, where fluids can be particularly viscous and laden with solids, the ability of a PCP to handle such characteristics is vital. The pump curve can help compare different models to find the best fit for the specific viscosity and flow rate needed.

Maintenance Considerations

Understanding the progressing cavity pump curve also plays a crucial role in maintenance. Regular monitoring of performance against the curve can help identify potential problems before they become serious issues. If the flow rate or head drops significantly compared to the curve, it might indicate wear, blockages, or other mechanical problems that require attention.

Conclusion

The progressing cavity pump curve is an invaluable tool in the operation and maintenance of PCPs. By providing a clear picture of pump performance across various operating conditions, it helps engineers and operators make informed decisions regarding pump selection, operation, and maintenance.

In industries where reliability and efficiency are paramount, understanding the intricacies of these curves can lead to better performance outcomes, reduced downtime, and significant cost savings. As the demand for efficient fluid handling continues to grow, the role of pump curves in ensuring optimal performance cannot be overstated. Understanding how to read and analyze these curves is essential for anyone involved in the design, selection, or maintenance of progressing cavity pumps.