Introduction

Trackhoes, also known as excavators, are essential machines in construction, demolition, and mining. They are typically equipped with a variety of attachments to perform different tasks. One innovative attachment that has gained popularity is the magnet. This article explores the benefits, types, and applications of magnets for trackhoes.

Benefits of Using Magnets for Trackhoes

- Increased Efficiency: Magnets can quickly pick up and move metal debris, reducing manual labor and speeding up the cleanup process.

- Safety: By removing metal objects from job sites, magnets help prevent injuries caused by sharp or heavy debris.

- Versatility: Magnets can be used in various applications, including scrap yard operations, demolition projects, and construction sites.

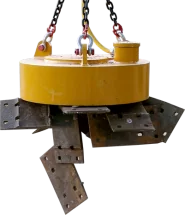

magnet for trackhoe

Types of Magnets for Trackhoes

- Electromagnets

- Powered by electricity, these magnets can be turned on and off as needed.

- Ideal for lifting heavy metal objects with ease.

- Permanent Magnets

- Do not require power to operate.

- Reliable for continuous use but may have limitations in lifting capacity compared to electromagnets.

- Magnetic Grabs

- Combine magnetism with a grabber mechanism to pick up large or irregularly shaped metal items.

- Effective in sorting and handling scrap metal.

Applications of Magnets for Trackhoes

- Scrap Metal Recycling: Magnets are widely used in scrap yards to efficiently gather and sort metal for recycling.

- Construction and Demolition: During demolition, magnets can quickly clear away metal debris, making the site safer and more organized.

- Road and Bridge Work: Magnets help in removing metal debris from roadways, ensuring a clean work environment.

Conclusion

Using a magnet for trackhoe significantly enhances the operational efficiency and safety of excavation projects. Whether for recycling, construction, or demolition, these attachments provide a practical solution for handling metal debris. As technology advances, we can expect even more innovative magnet solutions tailored for various applications in the heavy machinery sector.