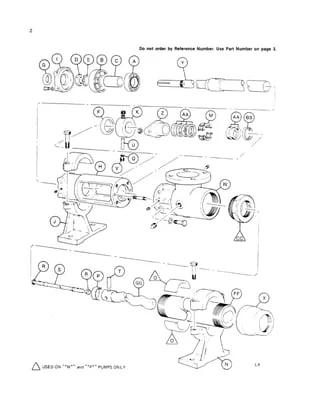

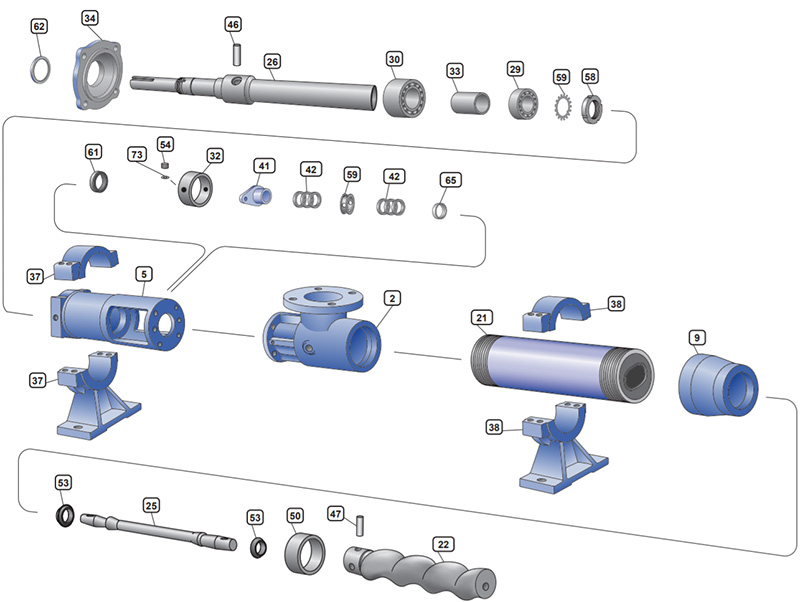

In the liquid transfer industry, Moyno pumps are widely favored for their excellent performance and durability. These pumps are usually used to transport viscous or solid-rich liquids, and their structural design focuses on efficiency and reliability. Understanding the various components of Moyno pumps and their functions is very important for maintenance and repair. This article will analyze the components of Moyno pumps in detail to help users master their performance and repair techniques.

- Pump body

The pump body of Moyno pumps is the main structural part, and its design determines the flow and pressure of the pump. The pump body material is usually corrosion-resistant and wear-resistant alloys to adapt to various harsh working conditions. In long-term use, the wear of the pump body may affect the efficiency of the pump, so regular inspection and replacement of the pump body is crucial. - Rotor

The rotor is one of the key components of Moyno pumps and is responsible for transporting liquid from the feed inlet to the outlet. The shape and material of the rotor have a direct impact on the performance of the pump. High-quality rotors are usually made of special polymers or metal materials to ensure long-term stability. Regular cleaning and maintenance of the rotor can significantly extend the service life of the pump.

- Seals

The seals of the pump are used to prevent liquid leakage and are another important component to ensure the efficient operation of the pump. Moyno pumps are usually equipped with multiple types of sealing systems, including static seals and dynamic seals. During use, seals may fail due to wear, so regular inspection and replacement are very necessary. - Drive system

The drive system is the power source of the Moyno pump and is usually driven by an electric motor or an internal combustion engine. The choice of the drive system is directly related to the working efficiency and application range of the pump. Regular inspection of the drive system to ensure its normal operation can effectively prevent downtime caused by drive failure.

- Overall maintenance

Regular maintenance of Moyno pumps is the key to ensuring their efficient operation. By regularly replacing wear parts, cleaning internal components, and inspecting the drive system, the failure rate can be reduced and the overall working efficiency can be improved. Users should understand the Moyno pump parts breakdown, understand the role of each component and the maintenance points, so as to extend the service life of the pump and improve working efficiency.