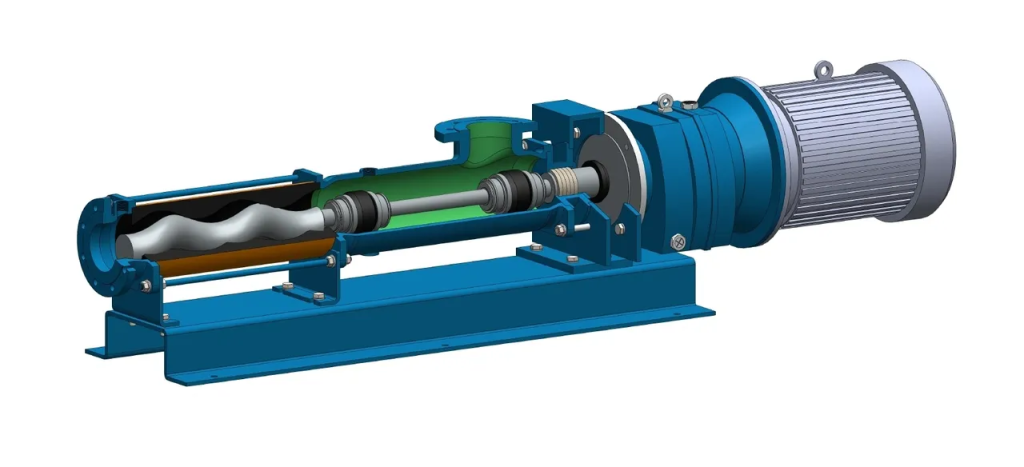

Progressive cavity pumps are great for gentle dosing of difficult media like solids and abrasives – even at high pressures and viscosities.

Self-priming and valve-less, they have unique capabilities. They can handle both low and highly viscous material, as well as solids like fruit and vegetables.

Thanks to high process liability and suction capacity, they are often used for continuous, gentle conveyance and the precise dosing of difficult media such as abrasive and corrosive fluids.

progressive cavity pump advantages

Good for solids and other difficult media

Can handle air entrained, multiple phase and abrasive fluids

Precise dosing

Suited to high and low viscosity applications

Allows continuous, gentle and low-pulsation flow

Self-priming

Does not vapor lock

Very accurate as a metering pump

High suction capacity

Reverse rotation and flow

Can be operated vertically

Quiet

Best applications for a Progressive Cavity Pump

Progressive cavity pumps are used in many applications, from wastewater treatment, to oil or food and beverages. They are well suited to solids, fluids with low to high viscosity, abrasive and toxic or corrosive media. Here are just a few of the potential applications for a PC pump:

Slurry and sludge transfer

Oils (non-lubricating and lubricating)

Cosmetics, creams, and lotions

Paint, varnish

Adhesives

Shear-sensitive fruits and vegetables