5 min read 4 Comments

Blowing Holes in MIG Welding: A Battle That Has Lasted for Decades!

Blowing holes is a persistent challenge faced by technicians when MIG welding car body panels. This issue has plagued welders ever since the introduction of MIG MAG welders to body shops nearly 40 years ago

(anybody remember the old BOC Autolynx) ? The phenomenon of blowing holes occurs when undesired holes form in the welded area, compromising the integrity of the joint

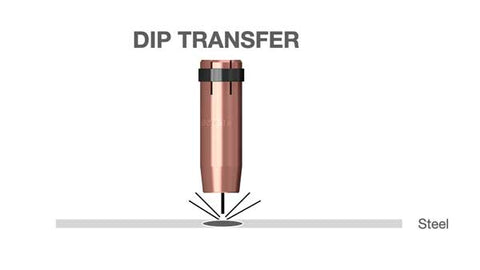

The DIP Transfer Welding Process: Aggressive and Explosive!

REASON ONE.

The DIP transfer welding process is known for its aggressive nature. It involves the wire “short circuiting” onto the material, creating an explosion that generates intense heat. This explosion melts a set length of wire, depositing it onto the material. A wire feed unit continuously replaces the blown wire, repeating the explosive process at a frequency of 50 to 60 times per second (50-60Hz).

These continual explosions in the same place create a weld pool (molten liquid metal), and we use this pool to fuse the materials.

This means that once the weld pool has developed the wire is then dipping into a liquid. If this then becomes too runny, the dipping of the wire creates a popping effect much like a needle popping a balloon, and this can pop it causing a hole. This popping effect is more easily obtained in thin steals as it’s easier to get the weld pool excessively liquid.

Always observe the weld pool size and how liquid it gets, we need heat to weld correctly and fuse to our joint, but too much heat can mean we either distort the vehicle panel or we do in fact “blow a hole”. Check out what is dip transfer welding.

REASON TWO

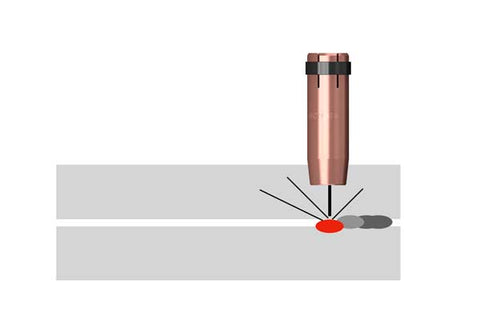

Butt Welding on Thin Steels: Mind the Gap and Heat Distribution! When welding a butt weld on thin steels, the joint preparation requires that there is a 1 mm gap between the two pieces of steel to be joined. Correct welding would mean the welding wire is placed right in the middle of these two pieces of steel, forming an equal liquid pool each side of the gap. If for any reason you heat one side more than the other this will cause excessive heat to build upon the edge of the steel getting it very runny. Again once the weld pool gets too liquid, the popping effect can then take place or the weld pool can collapse due to gravity.

REASON THREE

Welding Wire Diameter Matters: Size Does Make a Difference! The diameter of the welding wire plays a significant role in the welding process. The size of the wire determines the amount of welding current that can be generated. In the DIP transfer welding process, the wire is “shorted” onto the material, creating an explosion. The thicker the diameter of the welding wire, the more massive the explosion.

Welding wire diameter could be another factor. The size of the welding wire determines the amount of welding current that can be generated. Dip transfer welding or “short circuit” is created because we “short” the welding wire onto the material. Due to the voltage selected and the diameter of the welding wire, this will create an explosion. The thicker the diameter of the welding wire, the more massive the explosion.

Suppose your welding wire is the same thickness as the material to be joined. In that case, both essentially have the same melting temperature ( Steel often melts at around 1370 degrees C 2500°F) bringing in the scenario of “what melts first”, the material or the wire?

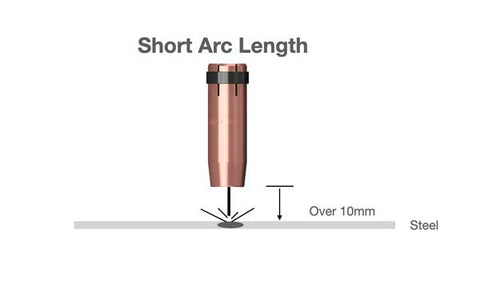

Generations of automobile welders and technicians have struggled with this when welding thin vehicle body panels. (some of the new steel panels are 0.67mm thick) meaning they go for thinner welding wires or increase their arc length to reduce the heat developed.

This could mean that the panel joint is incorrectly fused as now low heat is produced in the weld pool.

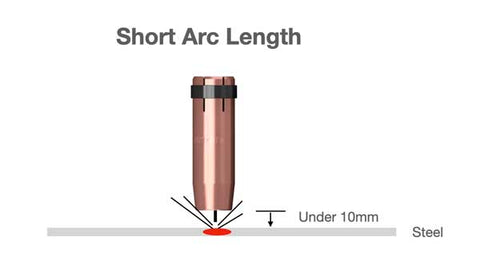

Arc length affects the amount of welding current you get. A long arc length means the wire isn’t under as much tension, so it takes less welding current to make it blow. A shorter wire sticking out of your contact tip by being closer to the workpiece means that it now takes a little more current to make it blow.

Heat Control: Trigger Time and Arc Length Take the Lead!

We need heat to create the weld, but what we don’t want is too much time of heat. It’s the length of time you weld that causes the problem not the amount of current or the diameter of the welding wire. Welding closer to the workpiece enables you to get your weld pool quicker as more heat is produced. You then control this heat, by pressing your trigger for a shorter time. To reduce heat when say you’re coming to the end of a joint, by merely drawing the nozzle back a few millimetres reduces the current and your heat will drop. It is possible by moving the torch inwards and outwards (arc length)to fluctuate the current by up to 20 Amps.

Heat, therefore, is reduced by trigger on, or weld-on time not by reducing the welding current.

The stop-start trigger action is a great way to weld thin steels, mostly when butt or groove welding as the cooling cycle can be controlled by how long you have the trigger off. This is how we reduce distortion whilst still ensuring the root of the weld is sufficiently penetrated.

Check out my post” how to weld on a car” for more tips and tricks.

To Sum Up!

– Blowing Holes in MIG Welding: A Battle That Has Lasted for Decades!

– The DIP Transfer Welding Process: Aggressive and Explosive!

– Wire “short circuits” onto the material, generating an explosion and heat.

– Continual explosions create a weld pool of molten metal used to fuse materials.

– Excessive liquid weld pool can lead to popping effects and holes, especially in thin steels.

– Butt Welding on Thin Steels: Mind the Gap and Heat Distribution!

– Correct welding requires a 1 mm gap between steel pieces, with equal liquid pool formation.

– Uneven heating causes excessive heat buildup on the edge, making the weld pool overly liquid.

– Liquid weld pool can result in popping or collapsing due to gravity.

– Welding Wire Diameter Matters: Size Does Make a Difference!

– Thicker welding wire diameter generates a more massive explosion during short-circuiting.

– Matching welding wire thickness to material can cause a dilemma of what melts first.

– Thinner welding wires or increased arc length are used to reduce excessive heat in thin panel welding.

– Heat Control: Trigger Time and Arc Length Take the Lead!

– More heat is produced when welding closer to the workpiece, enabling quicker weld pool formation.

– Heat is controlled by adjusting trigger time—shorter time reduces heat at the end of a joint.

– Arc length manipulation (inward/outward movement) fluctuates current by up to 20 Amps.

– Stop-Start Trigger Action: Welding Thin Steels with Precision and Distortion Control!

– Trigger action with controlled cooling cycles is ideal for welding thin steels.

– Distortion is reduced while ensuring sufficient weld penetration at the joint root.

4 Responses

Leave a comment

Comments will be approved before showing up.

Paul Jones

November 21, 2022

Replying to Sanju, Are you butt joining the bands and this is where the blowing holes occur? Alos you gas mixture seems high, can you not reduce the Co2 level to say 5%.

Regards

Paul