Types Of Saw & Their Uses

What type of saw do you use the most? There are more types of saws than you might think. We’ve put together this list of 40 types of saws and their uses to help you choose the right tool for your next project.

1. Traditional Hand saw

This is the most common type of saw. It’s muscle-powered, featuring a large, sturdy blade. It’s a great, reliable tool for cutting wood. Traditional hand saw blades usually have between 1 to 10 teeth per inch (TPI).

2. Hacksaw

Commonly used to cut through metal (pipes, steel sheets etc.), hacksaws are usually small and have thin, interchangeable blades.

The blade is tensioned in a C-shaped frame and has many small, sharp teeth. Hacksaws usually have around 14 to 32 TPI.

Hacksaws often have a tension nut too. This enables you to change the tension of the blade depending on your application.

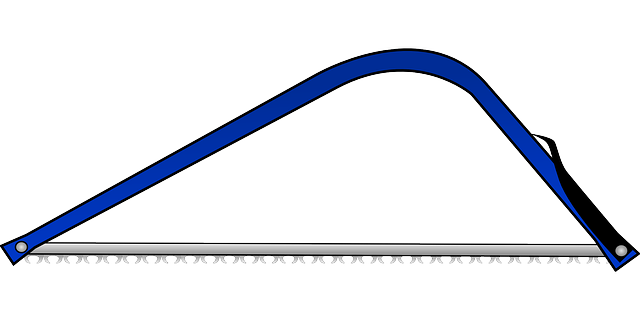

3. Bow Saw

A bow saw is a crosscut saw with a metal frame. This rough cut saw is useful for trimming trees, sawing logs and various other rough cuts. Bow saws have long blades with numerous transverse teeth that remove material when cutting.

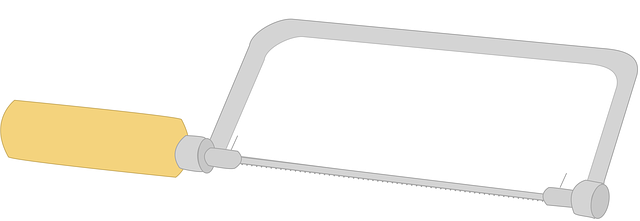

4. Coping Saw

A coping saw is mainly used for cutting curves in wood.

Different blades can be used in the coping saw frame for different materials, i.e. metal and wood.

The blade can also be removed, threaded through a hole in a material and attached back to the frame. This enables the cutting of inside profiles.

Coping saws are ideal for slow and precise cutting with a neat finish. Their blades feature tiny sharp teeth. Coping saws can have up to 32 TPI.

5. Fret Saw

Fret saws are great for precise sawing. They feature a thin, sharp blade and a large long frame that allows you to cut far into a material.

They have a drawback in that the blade cannot rotate. This makes complex cutting quite difficult. Fret saw blades are commonly available in 10, 15, 20 and 24 TPI.

6. Tenon Saw

A tenon saw is a type of medium-sized backsaw used for cutting tenons (a piece of wood used to insert into another piece of wood as a joint.).

Tenon saws are commonly designed with a short, stiff blade with a reinforced spine running along the back of the blade. Most tenon saws cut on the push stroke.

7. Pull Saw (Japanese Saw)

Japanese saws are woodworking saws that cut on the pull stroke.

Japanese saws are highly regarded because the pull stroke is more efficient than a push stroke and tends to leave a narrower kerf while cutting through wood.

They sometimes feature a blade with crosscut teeth on one side and rip teeth on the other.

Japanese saws usually have between 10 to 30 TPI.

8. Plastic Saw

Plastic saws are not made from plastic. They are made to cut through plastic.

Plastic saws become useful when you need to cut through plastic that is thicker than 25mm. They have very small and sharp teeth with a frequency of about 10 to 14 teeth per inch.

Most plastic saws are designed to cut on both the push and the pull stroke.

9. Insulation Saw

Insulation saws are designed especially for cutting insulation materials like expanded/extruded polystyrene and cellular plastic. They often feature waved toothing on the blade.

10. Dovetail Saw

A dovetail saw is a small type of backsaw that is usually used to cut dovetails (joints formed by multiple tapered tenons that interlock with corresponding mortises).

Dovetail saws often have lots of teeth (around 15 to 20 teeth per inch) that are sharpened in a rip tooth pattern.

11. Frame Saw

Also known as a tension saw, a frame saw consists of a narrow, flexible blade that is tensioned by a rectangular frame. They have two vertical bars (saw arm and saw bar arranged in H shape). Seldom used today, frame saws are designed for cutting wood & stone. When cutting stone, they were powered by water or wind in old fashioned stone mills.

12. Veneer Saw

Veneer saws are small handheld saws that are used to cut veneers (0.4 – 0.6mm thick sheets of wood). The veneer is placed on top of a surface and held in place with a ruler. Then, the veneer saw is pulled back along the ruler to cut the veneer.

13. Back Saw

Back saws are short handheld saws that feature a narrow blade with a reinforced top edge.

Back saws are great for cutting wood due to their sharp serrated teeth. They’re often used to create grooves or joints in wood applications.

The reinforced top edge enables more stable and precise cutting than many other types of saws. They’re great for cutting at an angle and where a constant direct cut is required.

14. Pruning Saw

A pruning saw has a long, curved blade. It looks a little like a knife and cuts during the pull motion.

Pruning saws are ideal for cutting difficult branches. They usually have between 5 to 12 TPI.

15. Bone Saw

Often referred to as butcher’s saws, bone saws are specially designed to cut through bone.

They resemble hacksaws but are longer and have larger, deeper, and wider teeth. This enables them to quickly and easily cut through flesh and bone.

Surgeons sometimes use bone saws in certain operations too.

16. Folding Saw

Folding saws have a toothed blade that folds into a handle (similar to a pocketknife).

Folding saws are compact and portable. They’re often used when camping for things like cutting small firewood.

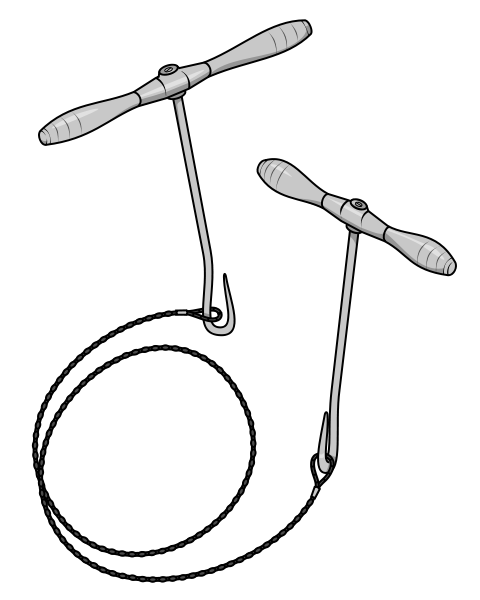

17. Wire Saw (Gigli Saw)

A wire saw is a saw with a metal wire or cable that cuts through material.

Industrial wire saws are usually powered, whereas hand-powered wire saws are used in outdoors applications such as cutting branches when camping.

Similar to band saws, wire saws rely on abrasion rather than teeth to cut material.

18. Compass Saw

Compass saws, also known as keyhole saws and jab saws often have short, fine blades and straight handles.

A compass saw is designed to make curved cuts (compasses) in tight spaces where larger saws can’t fit. This is ideal in applications like drywalling.

19. French Flush Cut Saw

French flush-cut saws are designed to cut quickly and cleanly on the pull stroke. These double-edged saws commonly feature a blade with 11 teeth per inch on one side and 20 teeth per inch on the other. They are ideal for trimming the ends of dowels, tenons and other protruding materials that are flush with a surface.

20. Floorboard & Laminate Saw

As the name would suggest, floorboard and laminate saws are great for cutting laminate and floorboards.

These types of saws commonly feature a high frequency of sharp, strong and long-lasting teeth on the blade.

21. Jigsaw/Reciprocating Saw

A jigsaw is a power tool with a reciprocating saw blade powered by an electric motor.

Jigsaws are often used to cut straight lines or irregular curves in materials including wood and metal.

Accuracy is an issue with jigsaws as they easily drift. Although, they usually feature a shoe at the bottom, which helps you guide the saw. It also surrounds the blade, making it a little less dangerous.

22. Circular Saw

A circular saw is an electric saw designed to cut straight lines in dimensional lumber, plywood, rigid foam board, and concrete.

Circular saws are a good substitute for a table saw if you don’t have one. They are useful for framing and cutting framing materials like wall studs, joists, rafters and sheathing.

A circular saws cut material with a sharp-toothed circular disc. They feature a handle placed behind the blade to reduce kickback. They are usually powered by electricity but are also available with a gasoline engine or hydraulic motor.

23. Table Saw

A table saw is a circular power saw that is mounted under a table surface. The blade protrudes through the table surface, and material can be run over it at different angles to achieve your desired cut.

A table saw is a great tool in a workshop as it is not very portable. It can be used for tasks such as ripping, crosscutting, mitring, and beveling.

24. Band Saw

A band saw is a power saw with a long sharp saw blade.

Band saws are very powerful, and the blade can be changed. This makes them useful for cutting many different materials, including metal and wood. They are like jigsaws in the way that they tend to drift.

25. Mitre Saw

A mitre saw is a power saw used to make accurate crosscuts and mitres. They make angled cuts based on the same principle as their manual mitre box siblings.

Mitre saws feature circular saw blade disks and steel guides that align the material that is going to be cut.

With heavy steel bases, they’re good for mounting on workshop tables for stability.

They also have adjustable arms that can be raised or lowered and swivelled from side to side to cut most angles.

26. Oscillating Saw

Also known as an oscillating multi-tool, an oscillating saw has a vibrating blade that’s great for making precise cuts in tight spaces.

Oscillating saws are quite small and usually powered by a battery or via a wired connection to the mains. A common application of this saw is cutting skirting boards to fit flooring underneath.

27. Chainsaw

A chain saw is one of the most common types of power saw. Designed to cut trees, it has a chain with teeth that move around the edge of a blade.

Chainsaws are very powerful and very dangerous. They are usually powered by petrol or electricity.

28. Plunge Saw (Track Saw)

A plunge saw is a power saw that is great for Longitudinal and crosswise cutting.

With a circular disk and optional guide rails, it ensures cutting material on a straight axis.

Designed for cutting wood, they are great for cutting, chopping, angle cutting and inclined cutting of different types of materials, such as multiplexes, PAL plywood, solid wood, aluminium profiles,

They also often come in a lightweight handheld design, which is very mobile.

29. Alligator Saw

Alligator saws look like chainsaws but are less powerful and work in a different way. They have two narrow blades that move in opposite directions. This gives accurate straight cuts and more control when cutting through construction materials.

30. Sabre Saw

A sabre saw is often referred to as a handheld jigsaw. It’s an electric saw that features a short, reciprocating blade and is more manoeuvrable than a jigsaw.

Sabre saws are often used to cut wood, steel or plastic. They’re handy and light, which makes them great for use in tight spaces like corners.

With versatile and easy to change blades, they can withstand great stresses and provide a high-quality finish.

They must be connected to an electrical grid to provide consistent power. Meaning they’re not ideal for remote locations.

31. Multi-Blade Saw

A multi-blade saw is a large industrial machine that cuts a wide range of materials, from wood to tiles and from laminated floors to aluminium and PVC. They are ideal in large workshops for making things like furniture

Multi-blade saws are great for deep cutting, they accurately cut straight lines, and they can be used with many different types of saw blades. The different types of saw blades include: diamond discs, Hss blades, and carbide-tipped blades (all available in most DIY stores)

32. Scroll Saw

A scroll saw is a small electric saw that cuts intricate curves in materials, including wood and metal. It has an extremely thin and narrow blade that cuts more delicately than a jigsaw but more easily than a coping or fretsaw.

Scroll saws often feature a plastic tube that blows away sawdust.

33. Radial Arm Saw

A radial arm saw consists of an engine and saw blade on a lever that passes over a saw table.

Radial arm saws can perform great composite cuts, cuts at an angle and more. They’re great for hobbyist and professional use.

They have high engine performance and make precise cuts whilst also being good for your back.

Always check the recommended speed for blades you use with a radial arm saw because some radial saws rotate very quickly.

34. Panel Saw

Panel saws can be vertical or horizontal. They are a type of power saw that cuts sheets of material into sized parts. Panel saws consist of a circular saw as well as support for the material being cut and a track for it to run along.

35. Tile Saw

Tile saws are ideal for creating clean, smooth cuts in tiles.

Tile cutters have very sharp blades. This enables them to cut through materials including ceramic, porcelain and stone.

36. Pole Saw

Also known as long reach chainsaws, pole saws consist of a chainsaw on the end of a long pole.

Pole saws are ideal for trimming hard-to-reach hedges, branches and trees where otherwise you would have to use a ladder. They reduce the risks you face whilst completing tasks like these.

37. Hole Saw

Hole saws, also known as hole cutters, are ring-shaped saws that attach to drills.

They make holes in many materials, including metal, plastic and wood without having to cut into the edge of the material.

Hole saws are available in many different sizes and materials that should be chosen according to your intended application.

38. Masonry Saw

Masonry saws are used to cut masonry units such as brick and tile.

Masonry saws are power tools often used in construction. They commonly feature a diamond blade that spins at a high speed.

39. Electric Hand Saw

Electric hand saws are manoeuvrable electric-powered saws. Available in many different styles and designs, they make work a little easier and faster at home or in a workshop.

40. Biscuit Joiner

Also known as a plate joiner, a biscuit joiner uses a circular saw blade to cut a crescent-shaped hole in two opposite pieces of wood. A biscuit (an oval-shaped piece of wood covered in glue) is then inserted into both holes to join the pieces of wood together.

Which Type Of Saw Is Your Favorite?

At Shop4Fasteners, we stock a huge range of saws. Head over to our saws category page to find a saw for your next project. If you have any other questions about saws, contact us. Call us on 0114 263 4422 or email sales@shop4fasteners.co.uk.

//