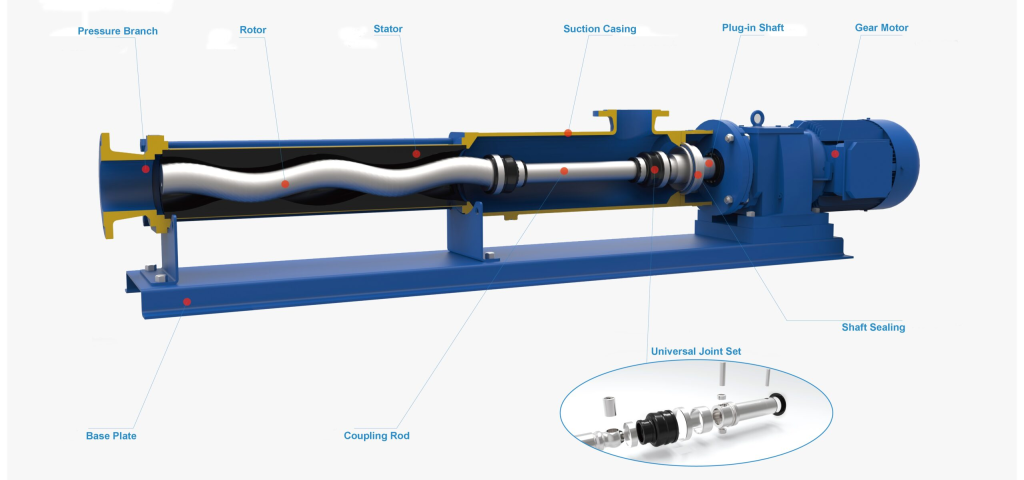

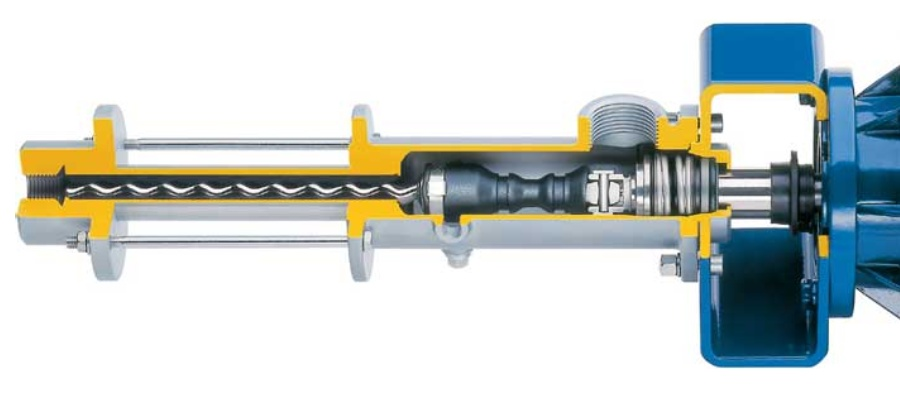

Flow control is a critical topic in industrial applications. Precise control of flow is essential in the chemical, mining, and oil and gas industries. In these industries, the progressive cavity pump is a commonly used fluid transfer device. This type of pump generates positive pressure within the pump casing through the rotational motion of a helical rotor, which then drives the flow of the fluid.

The progressive cavity pump, with its simple and reliable structure, good self-priming capabilities, and the ability to handle high-viscosity media, plays an important role in many applications. However, using the progressive cavity pump alone cannot fully meet the requirements for precise flow control. This is where the flow control system comes into play.

A flow control system typically consists of three main components: a flow meter, a control valve, and a progressive cavity pump. The flow meter is responsible for real-time monitoring of the flow data and feeding this information back to the control system. The control valve adjusts the resistance to fluid flow based on the target flow rate, thereby achieving precise flow control. The progressive cavity pump provides the necessary driving force for the fluid. Working together, these three components form a closed-loop progressive cavity pump flow control system.

Through the progressive cavity pump flow control system, operators can flexibly adjust the flow rate to meet various production needs. For example, in the feed process of a chemical plant’s reaction vessel, the addition rate of raw materials can be precisely controlled to ensure the stability of the chemical reaction. In the mining industry, the flow rate of extracted materials can be accurately regulated to avoid the impact of insufficient flow on production. In the oil and gas industry, the progressive cavity pump flow control system plays a critical role in the transportation of crude oil and natural gas, ensuring the reliability of energy supply.

In summary, progressive cavity pump flow control is an important flow regulation technology in industrial production. It combines the reliable fluid transfer capability of the progressive cavity pump with the precise flow monitoring and adjustment functions, providing high-quality fluid transfer solutions for various industrial applications. As industrial automation continues to advance, this technology will undoubtedly play an increasingly important role in the future.