.blog-menu-desktop ul {

background-color: #F1F1F1 !important;

width: fit-content;

float:right;

}

.blog-menu-desktop li {

display:inline-block;

font-weight: 600;

padding:0 15px;

vertical-align:text-top;

}

.blog-menu-desktop li a {

color:#000000;

}

.blog-menu-desktop li a:hover {

color:#E00519;

background-color: #F1F1F1;

}

.selected_category {

color:#E00519 !important;

}

.separator-border {

border-left:2px solid #000;

height:15px;

display:inline-block;

}

#misterworker-blog-menu .btn-primary:hover{

background-color: #e00819;

}

#misterworker-blog-menu-content ul {

background-color: #e00819;

padding: 10px 20px !important;

}

#misterworker-blog-menu-content ul > li {

margin-bottom:5px;

}

#misterworker-blog-menu-content ul > li > a {

color: #fff;

}

#misterworker-blog-menu-content ul > li > a:hover {

background-color: #e00819;

}

How to Choose the Right Hole Saw?

Published :

03/24/2020 09:00:02

Categories :

Mister Worker

, Professional working tools guide

Today on the Mister Worker ™ blog we are in the company of Massimo Castelnovo, Trade Manager at Stanley Black & Decker, to help our customers in choosing the Lenox hole saw that best suits their needs.

MW: What are the characteristics to consider when choosing a hole saw?

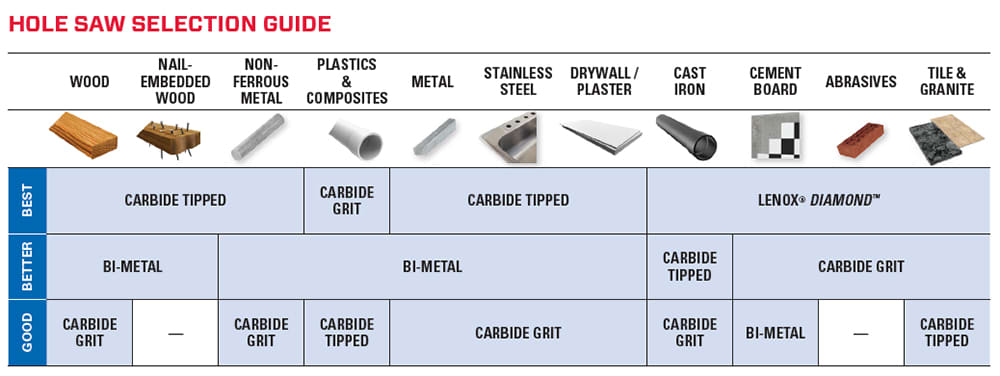

M.C.: The hole saw is an accessory that cannot be missing in the toolbox of a professional worker, or in the assortment of a DIY enthusiast. When choosing a hole saw, the most important factor to consider is the type of material on which the drilling must be carried out. Hole saws can in fact fact guarantee a reliable and precise hole on different types of material, such as wood, nail-embedded wood, MDF, laminate, aluminum, stainless steel, cast iron, non-ferrous metals, plastic, plaster, fiberglass, Corian, ceramic, porcelain stoneware, marble, slate, brick, and others. In addition to the material of the object to be drilled, it is necessary to consider the material of the hole saw, which can be bimetallic, diamond or carbide tipped.

In the Lenox range there are three types of hole saws:

- SPEED SLOT® bi-metal hole saws with T3 technology™, which offer 50% more durability and double the strength compared to the previous Lenox generation;

- Lenox Diamond™ hole saws with continuous, brazed edges to ensure greater durability on tile and stone;

- Carbide tipped hole saws designed for cutting tile and stainless steel.

MW: What innovative materials are used to provide a safer (less risk of breakage) and lasting hole saws?

M.C.: A quality hole saw has a structure made mainly of high-strength steel, it must have a robust wall and a reinforced bottom plate to significantly reduce vibrations. In addition, especially in bi-metal hole saws, the tooth design and the sharpness of the teeth are fundamental for the durability of the product. The presence of a percentage of cobalt equal to 7/8% guarantees the resistance of the saw against breakage even during demanding applications.

MW: How is Lenox positioned in the market of hole saws and how does it stand out from competing brands?

M.C.:The brand Lenox has been active in the global marker for more than 100 years. It has always been synonymous with quality and performance in the production of accessories dedicated to cutting and drilling operations. The first Lenox hole saws entered the market in 1959, since then Lenox has always stood out for the excellent quality/price ratio of its bi-metal, diamond or carbide tipped hole saws.

MW: Which products is Lenox most focused on in this category of articles?

M.C.: The most important range in this product category is certainly that of bi-metal hole saws. It is a complete range with the possibility of drilling holes from a minimum diameter of 14 mm up to a maximum of 210 mm. These saws are able to guarantee excellent results in terms of speed and durability on different materials thanks to the production technology which, for some processes, is covered by patents deriving from the great experience gained by Lenox in the sector of band saw blades for industrial applications.

MW: What are the advantages of the T3™ SPEED SLOT technology?

M.C.: The patented T3™ SPEED SLOT technology has greatly improved Lenox Bi-metal hole saws. Thanks to an exclusive design and an aggressive tooth shape, these products show an optimal cutting performance, speed and precision on different materials. These hole saws also require less pressure when drilling and reduce the tendency to block on thinner materials. In the case of drilling on wood, the SPEED SLOT side openings guarantee rapid material removal even on depths of 45 mm.

MW: What are the essential accessories to use with Lenox hole saws?

M.C.: You surely need an arbor to engage the hole saw of the required diameter. Generally, there are two arbor sizes, one for diameters from 14 to 30 mm and one for diameters from 32 to 210 mm. In the Lenox range there are also arbors called SNAP-BACK which guarantee a quick and tool-free replacement of hole saws.

Another fundamental accessory is the step drill bit that is mounted on the spindle, and is necessary to start the hole before moving on to the required saw diameter.

MW: What can we expect from Lenox in the future in the world of hole saws?

M.C.: In the very near future, September 2020, Lenox will renew the range of hole saws with hard metal inserts.

The new products will guarantee a service life 50 times longer than the current range, keeping prices in line with the current price list.

Subsequently, the main range of Bi-metal hole saws T3™ SPEED SLOT will also be updated with the new T4™ technology. Hole saws will be more performing and durable and Lenox will always supply customers with high quality products.