Cavity pumps, specifically progressing cavity pumps, are indispensable in various industries due to their ability to handle challenging fluids. Understanding the landscape of cavity pump manufacturers is crucial for making informed purchasing decisions. This guide will explore key aspects of cavity pump manufacturers, including their offerings, benefits, and considerations for choosing the right one.

What Are Cavity Pumps?

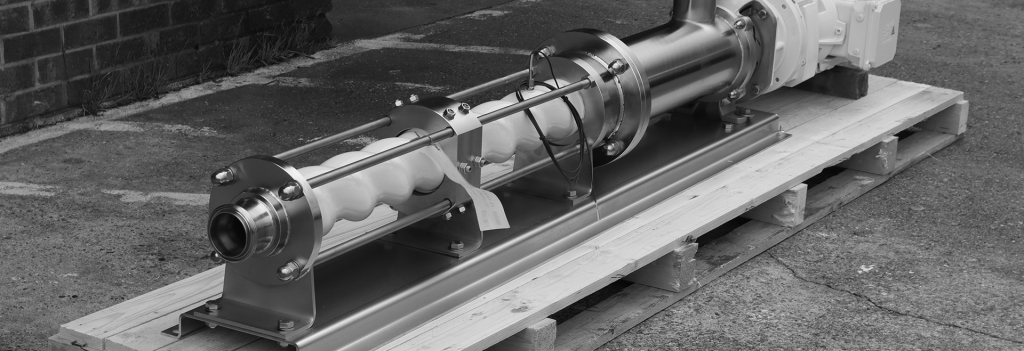

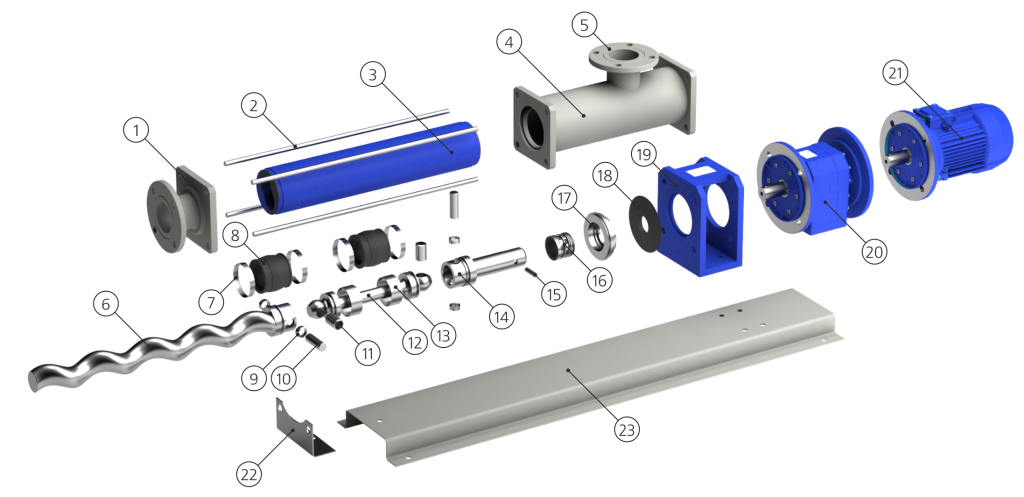

Cavity pumps are positive displacement pumps designed to move fluids through a helical rotor and stator arrangement. This unique design allows them to handle a wide range of substances, from thick sludges to viscous oils. Their efficiency and versatility make them popular in sectors such as wastewater treatment, food processing, and oil and gas.

Key Features of Cavity Pumps

- Continuous Flow: Cavity pumps provide a steady and consistent flow, which is essential for many applications.

- Self-Priming: They can handle air and gas without losing efficiency, making them ideal for varied operating conditions.

- Durability: Built to endure harsh environments, cavity pumps often feature robust materials that extend their lifespan.

The Role of Cavity Pump Manufacturers

Cavity pump manufacturers play a vital role in the production and distribution of these essential devices. Their expertise not only involves manufacturing but also providing support and innovations to meet evolving industry demands.

Types of Cavity Pump Manufacturers

- Global Manufacturers: These companies have a vast reach and often provide a wide range of products and services. They may have multiple production facilities and a strong international presence.

- Regional Manufacturers: Focusing on specific markets, regional manufacturers often tailor their products to meet local needs. Their understanding of local regulations and conditions can be advantageous.

- Niche Manufacturers: These companies specialize in particular applications or industries. They often offer customized solutions that address specific challenges in sectors such as food processing or chemical manufacturing.

Factors to Consider When Choosing a Cavity Pump Manufacturer

Quality of Products

The quality of products is paramount when selecting a cavity pump manufacturer. Look for manufacturers who adhere to international quality standards and have a reputation for reliability. High-quality pumps can significantly reduce maintenance costs and downtime.

Customization Options

Different industries have unique requirements. A manufacturer that offers customization can provide solutions tailored to your specific needs. Whether it’s adjusting the pump size or selecting materials that withstand certain chemicals, customization can enhance performance and longevity.

After-Sales Support

Reliable after-sales support is essential for maintaining your equipment and ensuring optimal performance. Choose manufacturers known for their customer service, technical support, and availability of spare parts. This can save you time and money in the long run.

Innovations and Technology

The pumping industry is continuously evolving. Manufacturers that invest in research and development are likely to offer the latest technologies, improving efficiency and performance. Look for manufacturers who are pioneers in innovative solutions, such as energy-efficient designs or smart pump systems.

Top Considerations for Your Purchase

Application Requirements

Before selecting a cavity pump manufacturer, clearly define your application requirements. Consider factors such as flow rate, viscosity of the fluid, and operating conditions. Understanding these needs will enable you to choose a manufacturer that specializes in your specific area.

Budget and Pricing

While quality is critical, your budget also plays a significant role. Compare pricing from different manufacturers, but also consider the total cost of ownership, which includes maintenance and operational costs over time.

Industry Reputation

Research the reputation of potential manufacturers. Look for reviews, testimonials, and case studies that highlight their reliability and performance. A manufacturer with a strong industry presence is often a safer choice.

Location and Logistics

Consider the location of the manufacturer in relation to your operations. Proximity can affect shipping times and costs, and local manufacturers may have a better understanding of regional regulations and market needs.

Conclusion

Navigating the world of cavity pump manufacturers requires careful consideration of various factors, including product quality, customization options, and after-sales support. By understanding the different types of manufacturers and what they offer, you can make an informed decision that aligns with your operational needs. Investing in the right cavity pump manufacturer will not only enhance your fluid handling processes but also contribute to the long-term success of your operations.