In the world of industrial pumping, reliability and efficiency are paramount. Seepex pumps, known for their durability and high performance, play a crucial role in various applications, including wastewater treatment, food processing, and chemical industries. However, even the best pumps require maintenance and occasionally need replacement components. This is where spare parts for Seepex pumps come into play.

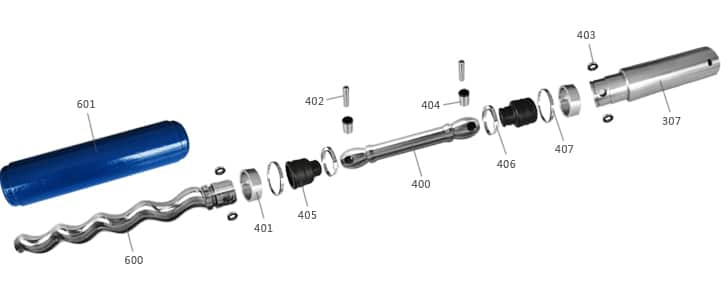

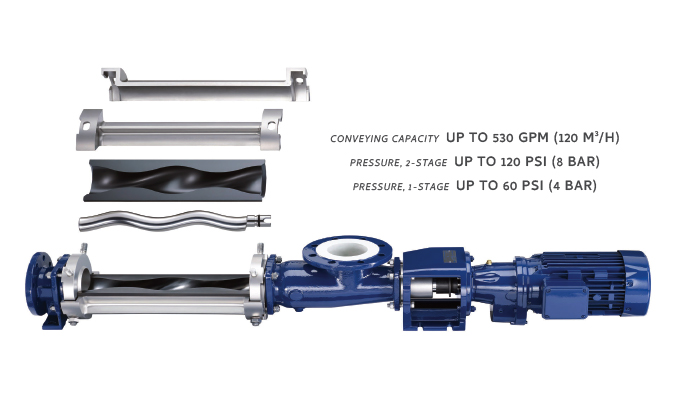

The significance of having readily available spare parts cannot be overstated. Pumps operate in demanding environments where wear and tear can occur over time. Components such as stators, rotors, and seals are subject to stress and can degrade, affecting the pump’s efficiency. Therefore, maintaining a stock of spare parts for Seepex pumps is essential for minimizing downtime and ensuring continuous operation.

When a pump fails, the costs associated with repairs and lost production can be substantial. Having spare parts on hand allows for quick repairs, reducing the time a pump is out of service. This can be especially critical in industries such as wastewater management, where a failing pump can lead to severe environmental issues and regulatory repercussions.

Choosing the right spare parts is equally important. Genuine Seepex spare parts are designed specifically for their pumps, ensuring compatibility and optimal performance. Using counterfeit or inferior parts can lead to further complications and may ultimately damage the pump, leading to more significant repairs and increased costs.

Furthermore, maintaining a good relationship with suppliers of spare parts for Seepex pumps can provide additional benefits. Reliable suppliers often offer expert advice on maintaining pumps and can help identify which parts may need replacing before a failure occurs. Regular maintenance and timely replacement of components can extend the life of the pumps and improve overall system efficiency.

In conclusion, investing in spare parts for Seepex pumps is a smart strategy for any operation relying on these essential machines. It not only enhances reliability and efficiency but also supports long-term operational success. By prioritizing maintenance and having the right parts available, businesses can avoid costly downtimes and ensure that their pumping systems continue to operate at peak performance.