A well-designed, well-built deck can transform a yard in all the best ways. But proper deck construction requires the right materials. You can’t just throw one together using whatever’s in your garage or tool shed and expect it to be safe for you, your family and your friends. Unfortunately, decks not properly installed can collapse under heavy loads, which of course can pose a danger to anyone in the vicinity.

In most cases, decks are connected on at least one side to a building, house or some other sort of structure. Whether you’re building an attached or detached deck, you should be mindful of the requirements and specifications for each to ensure you aren’t faced with any nasty surprises later on.

When it comes to building a deck, the type of fastener you use for this connection is vitally important. The safest and most common type of fastener used is the lag bolt.

Why use lag bolts for decks? For a number of reasons.

Using Lag Screws and Bolts for Building Decks

A piece of wood connects a deck to a structure. This piece of wood is known as a “ledger board,” or a “ledger” for short. Lag screws are the traditional and recommended way to attach the ledger to a building.

What size lag screws will you need? It all depends on your unique circumstances, but typically ½-inch diameter lag screws will get the job done.

- First, pre-drill 5/16-inch holes through both the rim joist and ledger.

- Then drill a ½-inch hole through the ledger alone.

You need lag screws that are long enough to extend beyond the band board by at least a half-inch.

You must know what you’re drilling your lag screws into. As mentioned, a rim joist is the ideal part of a building to drill them into, but there’s not always a rim joist to attach to when you’re building a deck. Avoid attaching your lag screws to a building’s drywall or fiberboard, as these materials won’t be strong enough to support the weight of the deck and those standing on it — it will eventually collapse.

Decking Screws for Decks

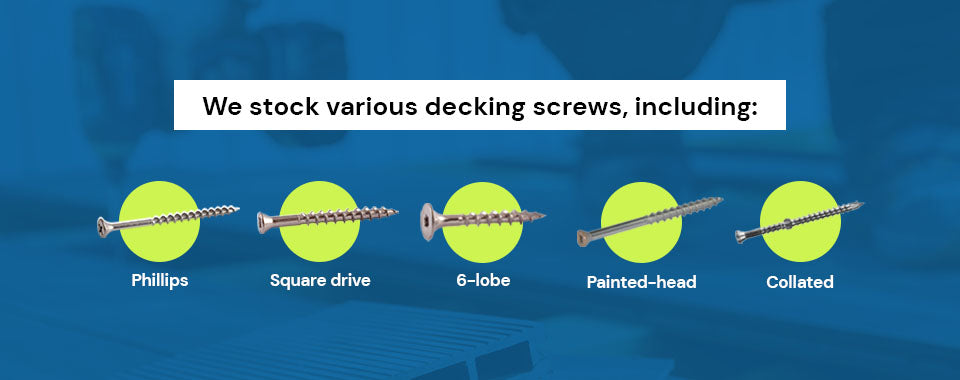

Lag bolts for deck posts are acceptable, but decking screws are called this for a reason. Mount heavy wood like timber and lumber safely and easily with the use of decking screws. Additionally, you don’t need an excess amount of washers, bolts and nuts to screw it in. We stock various decking screws, including:

- Phillips

- Square drive

- 6-lobe

- Painted-head

- Collated

These screws differ in design and coating. Some are yellow zinc-plated, dacrotized, W.A.R. coated or stainless steel. Our painted-head selection allows you to match the screws with the decking. With a wide variety of decking screws, lag screws and bolts, you could even try a few of each to see which is better for your particular job and send the rest back. If you aren’t happy with the fasteners you choose, we will take them back without hesitation.

Lag Screws

Lag screws are fairly inexpensive, which is a bonus. But be sure to get stainless steel or hot-dipped galvanized screws for optimal performance. Invest a little more to get lag screws requiring no pre-drilled holes. These special lag screws often have washers attached to their heads. Also, if you can get behind the house’s rim joist, you can use through bolts as an alternative to lag screws. Use carriage bolts to secure your deck to the house, then secure the carriage bolt in place by attaching a washer and nut on the opposite side of the rim joist.

Never use nails to attach a deck to a rim joist, as nails can’t offer the stability needed to hold the deck, much less people standing on top of it.

Keeping You Safe

The No. 1 challenge in building a deck is the safety of those who are going to use it. When decks are suspended in the air, this is particularly important. But even decks built low to the ground can pose significant safety issues if not properly installed. Never take shortcuts when building a deck. It’s tempting to fasten to fiberboard, use nails or even chisel out a portion of the rim joist so carriage bolts that are too short can be capped with nuts and washers. But each of these shortcuts will damage your deck’s integrity and lead to dangerous situations for you, your family and your guests.

The best types of screws you can use are those with sharp, elongated tips and deep threading. They drive far into the joists to secure the conjoined pieces tightly. Using the right screws and tools is one way you can have peace of mind knowing you’ve done your best to keep your family safe when they eventually enjoy the deck.

The Best Screws for Pressure-Treated Wood

Pressure-treated wood uses chemicals that can accelerate the appearance of corrosion unless you use the appropriate fasteners. When building a deck that features pressure-treated wood, use galvanized screws whose galvanizing thickness is between .75 and 1.5 millimeters. Look for galvanized materials from A153 to F2329 to achieve this thickness.

While you may hear that you need double- or triple-dipped galvanized fasteners, this is a misconception. In reality, double- or triple-dipped galvanized fasteners will need a zinc coating to be useful in deck construction.

Different Types of Bolts

It’s good to have options when it comes to using bolts and screws to secure your deck. Here’s a summary of the various bolt types and what they are commonly used for:

- Carriage bolts: Include A307 Grade A zinc, Grade A galvanized bolts, Grade 5 zinc and 18-8 stainless steel bolts. As their names suggest, these bolts are zinc-plated, hot-dipped galvanized or stainless steel and are all used to attach wood to another piece of wood or to fasten wood to metal.

- Hanger bolts: Fully threaded zinc and stainless steel bolts typically hang metal from wood. Though you may not use this for your decking project, knowing its purpose may be useful when you embark on other projects.

- Hex bolts: Hex head lag bolts and hex lag screws are ideal for joining wood together. They make your job easier due to their prominent, sturdy design. Because they are longer than the average bolt, they could be entered crooked and pierce the surface, which is why you should first check that the wood you’re connecting is in good condition before fastening it.

- Elevator bolts: These are also useful for decking projects. Elevator bolts withstand pressure, weight and external elements that could lead to damage and corrosion. Their locking necks reduce movement that could cause a structure to buckle.

All bolts are manufactured in the strongest material for maximum durability. They are made to bear the effects of rain, sunshine, moisture, snow and ice while carrying hefty weight loads. Where safety is concerned, FMW Fasteners does not compromise.

About FMW Fasteners

When you need bolts for building a deck or you want to know where to buy decking bolts, come and discover the wide selection of fastening materials you’ll find at FMW Fasteners. We offer this huge selection so construction professionals and do-it-yourself enthusiasts always have access to the high-quality materials they need to deliver outstanding results on projects of all kinds.

You can always enjoy quick shipping when you shop with FMW Fasteners — and orders over $100 ship free. Order bolts for decks in the exact quantity you need rather than the fixed amounts other providers insist on. If you have bolts or screws left over after your project that you don’t need, you can return them at any time as long as they remain in like-new condition — there’s no expiration on returns.

Make sure your deck is the venue for outdoor enjoyment that it should be. A quality project demands quality materials, and that’s just what you’ll find at FMW Fasteners. No matter the size, specifications, and metal type that you need, you’ll find multiple options in our generous selection. Choose FMW Fasteners when you need only the best bolts for building a deck.